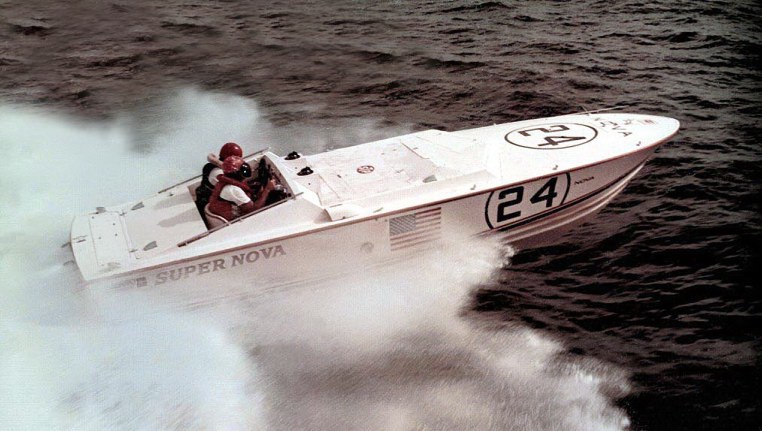

THE SUPERNOVA 24 RACE BOAT

THE SUPERNOVA 24 RACE BOAT

____________________________________________________________________

The Dream And The Reality.

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

SuperNova19.com and SuperNova24.com

Is Proud To Announce That We Have Recently Purchased

The SuperNova Race Boat.

We would like to thank Ferd for all the hard work he has done and for the chance to continue and complete it, bringing this piece of history back to life.

We here at SuperNova19.com plan on restoring the boat as close to original as possible. Hopefully within 2 years before it's 42st birthday we will be ready for the first test drive. It will be a challenge but with a boat like this there will never be a loss of motivation.

The Nova 24 Race Boat is coming back!

Be on the lookout.

____________________________________________________________________

With that announcement it begins and from here everyone gets to follow along. We take a lot of pictures just to have reference's to look back to. The good thing about that is we always have more pictures then anyone wants to see of a restore.

____________________________________________________________________

The Reality

June 2009

____________________________________________________________________

I finally went off the deep end.

I finally went off the deep end.

6/25/2009

This all started by knowing I was about to finish off the house we bought over the winter. Being there was one room that was left I decided to pick up a side project just for the fun of it. So I found a 1973 19’ Monza last fall in need of work. Most of the major work for it was done over the winter. When this spring came, when it was not raining, the boat was painted and put back together. It still is not finished yet (still waiting on exhaust) but it's done enough for me to start the hunt for a new boat to redo.

I figured I would start now and that way I could get it bought over the summer and when fall came hopefully I would already have a jump on things.

To tell the truth I have no clue why I'm even doing this. I have a boat and it a nice boat and most of all it could be redone again to make it perfect but I'm having to much fun with it for a change. I have big plans for it and to take it apart means it will be apart for a while. Knowing what I do I made myself a deal, sell the Monza and find another boat worth doing or keep the Monza for a year while I redo the Nova.

So I throw out a couple feelers to see if anything is worth it. I was interested in doing another 19 and almost went for it with one in New Jersey but I don't know, it was there and if I wanted to I could if nothing else better popped up. For me not to do another 19 knowing what I know it would have to a once in a lifetime boat.

I only knew of one like that and it was not for sale. Just to make sure nothing happened I have been keeping an eye on it for years. Talking to the owner now and then. Wishing (and making sure it was known) it was mine but never made an offer on it. It was now or never. If I got another 19 it would be 2 years before I was done it and “Time Warp” and who knows what could happen between now and then.

So I go over to Ferd’s shop and after a couple “hi’s” I ask the question. Just like with the Monza it’s either I can or I cant and then be done with it. So I say, “Ferd will you sell the SuperNova race boat to me?” His answer, “Ya, I sell it to you” and now we just jumped the biggest hurdle of all but at the same time I just made him realize he would sell it. What was a safe and hidden fantasy for me was now out in the wide open for anyone to take.

Now the main question for me, to be in the running was, how much? After an hour of looking thru the yard for the trailer and other stuff and me telling him how poor I really am Ferd made me an offer. Lets just say I had to go home and think about it and then the wife had to think about it and then the loan officer had to think about it. This was not a fantasy or backyard buy at all, it was the real deal. By the end of the week all the ducks got in their rows and I stopped by Ferd’s to tell him I would take it.

He seemed surprised to see me back. I told him I would be back the first of the coming week with a check.

On Monday I stopped by again with a check. Ferd was out right shocked to see me IMHO. And after bit the deal was done.

The Race boat is coming home to Supernova19.com. How cool is that!

To start things off, the trailer is coming home this weekend. It’s been sitting 20+ years. Surge brakes are shot, lots of rusty metal. No rot. It’s as solid as the day it was made. Tires are dry rotted. No lights and who knows what else. Either way, I have to get it fixed and painted before we set the 24 on it.

Speaking of tires…..what a way to start a thread.

4 - 8 Ply 205 X 15's

____________________________________________________________________

6/27/2009

The trailer is here.

Only lost 2 hubcaps (they were rotten anyway) and one lady jump off the sidewalk on the way home.

And it needs work.

Had to take one tire off because it was locked up. I tried to put the wheel on and drag it on the road to see if it would break loose. No such luck and after a little while of that I had enough and took the wheel back off and stuck it in the yard.

The first thing I noticed was the trailer was in great shape but then I also noticed it was f___ed. The trailer company made the top beam and the second one, you can tell when you look at them. The top one needs a little welding (there’s that word again) but its 95% there. The bottom beam on the other hand is really thin. They put in a “L” piece of metal between the carriage and the trailer beam and it turned to dust. All of it. There is even a hole popped through one of the sides.

There is also a considerable amount of room between the sides of the carriage and the trailers beam. This gap was filled from the “L” metal before. So as I'm beating all this crap out and I'm thinking a new bottom beam, new “L” beam to fill the gap ... and why was the “L” beam there anyway?? As I look up at the Monza’s trailer sitting there it hit’s me. Aluminum 3” square tube, forget about the “L” beam and replace the trailers first beam with the bigger box beam. Bolt it to the next solid trailer beam. Thru bolt the carriage to it and off we go. Should be good for another 50 years.

The Attwood breaks are shot. Took about an hour to get this assembly off. The axle is OK I guess but I have not cleaned it yet. Both breaks sets are now sitting in my garage just in case. Which brings me to my next issue. Where the trailer hooks to the ball. The trailer ends the same place the winch stand and the surge break assembly extends it. Not sure what to do there. Which brings me to a third question. What am I going to use for a bow stop when all I have is a stub.

____________________________________________________________________

6/29/2009

Lots of dirty work. Drill with a wire wheel and a disk sander for hours. A coat of paint really changes the whole look of things. I made it half way through. I know painting should not be on the top of the list but the damn thing looks so bad. I'm using a flat black paint on it. It's not primer, just flat. It makes the metal look real good. I did try some gloss but that came out to pox marked. So flat it is and should be easy to maintain.

The metal should be here this week to fix the trailer carriage. Along with the 2 new screw jacks and "ROCKET" stickers.

T-25 = 25' trailer / 144 = trailer number / 69 = 1969

____________________________________________________________________

7/5/2009

The last two days I worked on the trailer. The major work is now over. I got the new square tube in under the trailer and the carriage is now attached. I think I may add a couple more bolts to the middle rail and the top rail just to back up some of those 40 year old welds. I'm glad I line marked up the trailer real good on how the carriage went back on. The first side never moved but the second side did and I had to get it back in place. Without the marks I would have had a right turning trailer. I didn't get pictures of the final paint but it is all done. Now a lot of small stuff.

On Friday (7/3/2009) I went to North Carolina to pick up these.

____________________________________________________________________

7/12/2009

More work done to the trailer. Got the electric winch installed and finally figured out a bow stop. I've got the right bolts for the center hook up but I just haven't got to putting them in yet.

I also found out that after I had custom made “Rocket” stickers made for it the trailer is really a “Thunderbird” trailer. Imagine my surprise. Oh well, things could have or still can go much worse.

All the wheel bearings came in. That’s a relief. I thought I would never find them at one point. I ran out of places to look local and there is few. On-line I found one place that had one bearing size and another place for the other bearing and another place for the seal. Now I'm just waiting on the seals and that major thing will be off the list. Two more big steps left (welding and surge breaks) and it will all be good. Even the serge breaks can wait being I'm only towing it 7 miles for the next year or so.

I hope to get the boat home by August.

____________________________________________________________________

Big Update

Big Update

7/13/09

Nothing on the trailer. Still waiting on the seals to show up before I do the wheel bearings.

I did make a deal for the cracked 454. He is shipping me a complete 454 car motor and transmission. He is also going to pay for the gasket set and I'm doing the labor out of the kindness of my heart. I may just look for a block for this motor I have now and keep the other motor intact as a back up. Who knows but at the moment I need another motor like I need another hole in my head.

Now I will have 5 motors, 3 trailers, 2 boats, 1 that runs (I think) and a major screw up on my timing schedule.

Why do I do this to myself?

____________________________________________________________________

7/17/09

I'm kind of milling about the last couple days. There’s things to be done but I am running out of stuff until I get someone to do them (welding). There is about 5 places that need a tack or two. Two of them is in the picture. One is the little brace that holds the fender up and the other is the upside down pump jack has too be tacked so it don't slide down with the boat sitting on it. Oh and there is a third, that little gray roller that sticks up could use a little fix also.

I worked on the serge hitch most of the afternoon. I managed to free it up and got it working good. The master cylinder is shot but I found a new old one the other night so that’s good. I also found a rubber line kit that would work It only cost 175 bucks to get back to the drums. They on the other hand are another story. They need to be turned. New shoes and actuator. I think I can salvage everything else.

The bearings did come in just not with bearing cups. I plane on doing them this weekend and even thought about reusing the cups that were already in there but I could have used a grinder on it and not got the pits out. So back to the hunt . 45 bucks later I have cups on the way (be here Tuesday ). So it’s official. 200 bucks for wheel bearings on this monster. Just so it can travel 7 miles and sit for the next who knows how many months. Add in all the metal, paint, winch, rollers, bearings, jacks, tires, brakes parts, lights, wood ………….. This is the most expensive boat I have ever had and I don't even have it yet.

It’s amazing what a coat of paint will do.

____________________________________________________________________

7/19/09

All the welding is done.

____________________________________________________________________

7/20/09

I have been looking for this thing every time I go to Ferd's. I found it today. Sadly it had been run over. But with a little sheet metal riveted in and a bunch of pounding it's back on.

____________________________________________________________________

7/21/09

Had a bit of a setback today. All the races showed up and I started to do the wheel bearings. The locked up wheel (the first), even though it took 20 minutes to beat it out the race when the new race went in it was to small. I guess the old race and bearing got burned up at some point. So at this point the only option I have is to sleeve the hub for the race. I just happen to have some 3/8" wide, super thin roll of stainless steel that will work. I think I may just luck out with this one. There is no other option. The hub is no longer available.

____________________________________________________________________

7/26/09

Where to start? It’s been a few days.

For the most part I have been just plugging away. Fix this, install that and then fix it again.

I got the lights done. Don't seem like much but a bad ground screwed with me for a afternoon. After adding a second ground wire to the back half of the trailer it was fixed but I will never get that time back.

I'm still waiting on the master cylinder. I think it will be here Monday. Maybe.

The new rollers should be here the beginning of the week also. Just the two gray ones that stick up. The rest are fine. It’s just those two are just a little flat and getting close to the metal that holds them.

Wheel bearings and seals have been done. All grease packed and “good to go“. He says with his fingers crossed. This trailer has burned up a set of bearings or two in the past and it really didn't have much use. I wonder why? My best guess is no maintenance and it sat a lot. I guess I will find out soon.

When in Delaware I got the rotors cut. It was a little scratchy if they could be saved when I looked at them but they are thick and didn't take that much to clean up considering how bad they looked.

When I started to look for parts to rebuild the brake backer plates I found for the price of a set of pads alone I could buy all new backer plates built. Being I needed everything except for the plates themselves it was a “no brainier” to buy the kit and it made it pretty easy to install also. To look in that box and look at the plate…..wow! How nice it is.

The tires were finally mounted on the rims. Even though they were bought first they were one of the last things done. As usual the boys down south hooked me up. New screw in brass valve stems and the use of a “cheater” to get the tires to bead. If you have never saw a cheater used you missing a treat, unless you are the one that never seen it used and had your back to it. Scared to piss out of me.

So as I was screwing around with the last wheel (the one that was locked up before) doing a little cleaning up of the hub and wheel getting it as right as possible I knock the trailer off the stands. I had been yanking on it all day and it was sitting on stands in wet dirt on unleveled ground. One to many yanks and I was holding the drum and hub and the trailer just moved away and on to the ground. So that made up my mind that the tires should go on the trailer.

I think I can see a light at the end of the tunnel. If I can get a couple things wrapped up the next couple days it should be good for a test drive by the weekend.

Wait a minute ………….test drive…………………..I'm taking about a trailer? …………..a boat trailer?

____________________________________________________________________

7/27/09

The rollers came in today and were an easy install. Go figure. I have a basket of tools at the ready and it took a pair of pliers and channel locs and it was done. I also started to lay out the brake lines but I'm still waiting on the master cylinder. Got to get it before final install.

And that's about it to be done.

The Last and soon, The First.

____________________________________________________________________

Coming to an end.

Coming to an end.

7/29/2009

In spite of the rain the last two nights I got the brake system installed. I still need to fill and bleed the whole system but I wasn't going to do that as wet as its been out. Water and brake fluid are not the best of friends. But it’s done down to wire looms over the hoses anywhere they go over a dull edge (there are no sharp ones).

Everything but the hitch cover. After prettying it up a while back I had to beat the hell out of it to get it to fit over the master cylinder. The m/c is identical to the old one but the brake line comes out of it just at a slightly different angle so the cover will have to accommodate it. Not sure if it will fit yet due to the rain happening again. I'll have to try again tomorrow.

So it’s bleed brakes, put cover on and start dragging it around.

If I ever need something to work it’s now. The trailer has drained the money well dry. I'm so broke that all the kings horses and all the kings men……….. If something major bad happens I may be paying storage fees for the boat over the winter.

____________________________________________________________________

Happy Birthday

Happy Birthday

8/7/2009

It sure is intimidating up on it pedestal.

I had about 10 minutes to look at it in the light over the last two nights.

This boat is sick!!!

I have to build bigger bunks for the trailer. For that matter I'm not even sure about the trailer. Backing it in the driveway (a very hard turn) I saw one of the wheels bow out. Not sure with these torsion axles if it’s supposed to do that or not?

The most forward trailer roller doesn't come within 3 inches of the keel and its welded on. I also have to adjust the bow stop but that should be no big deal. All and all its just a big question mark after the first ride. The trailer does sit nice and towing it, I would haven't even known it was back there besides the fact that I was staring in the rear view mirror the whole way thinking it was going to roll off the trailer into the middle of Mountain Road during rush hour. All I kept thinking is, “I don't want to make the news tonight” but all was well.

As it sits in my driveway I have a 6’ tall step latter that the top of it is level with the transom’s deck. I'm going to need scaffolding just to paint it. When I stand inside of it, it’s so tall I can see Russia from house.

So like I said I've had minutes to look at it last night and then tarped it and didn't even take it off tonight but this is what I've observed of everything so far.

The boat is built the best I have ever seen a boat built hands down.

Not a single jell crack any where. 40+ years. Not sure if it was Ferd or Brownie but its near perfect.

The glass is thick and solid. I always said that I could drive my 19 thru a lesser boat and come out the other side ready to go. The 24, I could drive through that boat and the dock it sat at and still be ready to go.

The boat has no waves in the glass. Nothing, notta, not a one. The sides of this boat are smoother/straighter/cleaner then the sides of my van.

It looks to have two massive gas tanks. Big enough tanks for hundreds of gallons of fuel and they are built into the sides of the boat. I'm not sure if they are glassed in metal tanks or if they are only fiberglass. If they are glass alone I'm thinking I may have some issues.

Many things I don't understand what they are and how they work. Pipes, pick ups, holes that I have no clue about. I will have to shoot some pictures.

Believe it or not but the 19 is bigger then the 24. At least in the ass. The 19 is 7’11” across at the top of the transom. The 24 is little over 7’6”. There is almost 4 inches difference.

The Vee on the 24 is only about 2 inches deeper then the 19’s (if you account for the round bottom of the 19 and the sharp Vee of the 24). Besides that the transoms are the same except the 24’s looks shallower or not so bulbous (if you can understand that).

When Jack (my son) saw it coming down the street last night the wife said he lost his breath and then started freaking out. Now boats to him are normally just something to pull him around on a tube or crab from (there is no chicken necks going in my boat). I will be outside flushing the 454 and it sounds gooooood. Jack will walk right by with no notice. At his age I would have took a shower in the exhaust water I would have been so in love.

But this one got him. Wait until I start plastering big ass numbers on it.

Then there is the wife and financial advisor. Being that it makes the house look small, fills the driveway, there's no bunks, no cabin, no seats, standing room for 3 (we are a family of 4), insane gas hog, knowing buying the boat (for a lot more then we can afford but a deal I couldn't pass) was just the beginning, no windshield, having to buy two motors a week after we took the hit for the boat because it was another deal we couldn't pass and last but not least there is no bathroom.........I expected the worst. The boat is not “turn key” by a long shot for as much as we paid for it and you know first impressions.

Maureen never saw it before yesterday except for a couple pictures and you really have to see it in person to get the full effect as it makes you squeal like a little girl.

She had 6 to 8 weeks of wonder while I spent all my time and money beating the rust out of this big black trailer.

So as I pull up knowing the boat doesn't look its best I think I need to start giving the, “you know what I can do speech” and “it wont cost that much speech” and “it will be worth it in the long run speech” as soon as I get out of the truck. I never had to say a word. The boat sold it’s self before it got to the driveway and I got the impression she was pleased with the deal. And trust me she knows where every dollar came from and how it will get put back again but she was pleased.

And last, Maureen stopped by the boat ramp where the sunset watchers, fishing folks and beer drinkers join up for neighborhood talk and the 24 is the talk of the neighborhood. Kids asking if they can come by and look at it. Adults wanting to come by and look at it. I think tomorrow I'll uncover it and get nothing done all day.

It nice that everyone has an eye on this boat. Good security but a lot of pressure.

It's been a very good birthday and it's official.

____________________________________________________________________

I'm Lost

I'm Lost

First, some pictures have been requested so here we go.

Here in the first picture I'm standing on the top step of a six foot latter. Scary.

The second is standing on the bow. Come to find out the deck plates that cover the motor are so new that they have never had paint put on them (one of the reasons they are dirtier then the rest of the boat). Also the dash and the rear engine cover haven't either.

Looking through the rudders cut out of the transom. You can see all the way to the front structure wall (about where the cabin would start). That board you are looking at is the deck of the cockpit. As you can see there is no firewall's at all from front to back. That has to change even if its just chicken wire.

Here is one of the most interesting things of the boat. I learned many years ago before they had trim or trim tabs they used to pump water in and out of this tank to add weight to the bow. But then I've been told recently that in this boats case it was used to ballast the fuel load. I would love to use this space for a fuel tank but this piece is to unique to even think about taking out.

Also extra ribs for taking the big waves.

The gas tanks are those white boxes on either side of the deck. They are so big that they even hold up the seat bolsters. If I could find a better place to install new tanks I would turn them in lockers for boat stuff. That way they could still hold up the seats and give me storage.

You can see all the way to the transom. And of course there is leaves. About a big black trash bag full. A couple full shop vacs and a power wash later and it don't look much better. But it semi clean. Spent about 6 hours on it just getting it clean enough for the new cover and finding things along the way.

I usually get a chance to take a boat apart before I start building it. That way I can settle into how I want to do it. This time I have motors over here, hull over there, drive parts over there and not a one that I took off. I keep looking at it thinking where to start. It’s August. The motors can wait until it gets cold. The garage will be warm enough until January. Do I hinge up the doors and start prepping it for paint. It has to be done before anything else. I think if I start on it in a week or two I could have it painted inside and out before the end of fall.

Anyway around it I have to come up with a plan before I do anything. More of that later.

And for the Nova24 owners.

Just to show it is an original. Even though it doesn't show on the outside thanks to Ferd this is the front hatch.

And here is the cabin entrance. Again you cant see it on the outside.

A look at the transom.

The two pipes together are water pick ups for the motors. The middle one I have no clue, maybe a transmission cooling something and the bottom is the outlet for the front ballast tank.

As for the trailer debate. It is a 25’ thunderbird trailer and is rated for the boat. The boat looks big on it in the pictures for some reason but it dose fit nice. I think one of the reasons it sits so high on the trailer is because of the prop shaft angle. The lower arrow is the front shaft strut and the higher arrow is where the second strut goes. This prop shaft comes down at a steep angle. Add a prop to it and you need every bit of height it has. There also is a big ass rudder that has to go back there and hang down. I'm thinking a new trailer may be a little hard to find.

Yesterday was bit of a busy day.

When you have a Fed Ex truck like this show up you know you are getting something.

Along with the big truck there came a smaller brown truck and a little white jeep all bringing gifts (that I had to pay for).

One of the things that came was a new boat top from Classic Accessories. With a name like that you know I had to buy it. Upon first inspection, for a $160 this thing is awesome. It's brand new off of an eBay store and that was the price. No shipping $$ or anything else. It fits very well but will need a little customizing being I don't have a windshield and the straps would work on a normal trailer but this boat sits so high on it a couple came up a little short but that can be fixed. But again it’s a nice top. Thick as canvas and stitched up nice. Not a bad color either. Now I won't have to worry about the leaves that end up sitting on the hull until the wind blows again and replaces them with new leaves or the occasional dirty hand grabbing it. It even comes with a pole for the center. It gets an A+ for the first impression.

Now the big truck brought something else. It’s another 454 from the guy I bought the 2 motors from that one ended up having a cracked block. The motor looks good over all but I am had second thoughts about it. I haven't got a hold of the guy yet but I was really worried about what year this motor is. If it’s to new it will have a 1 piece crank seal and that will not work with the flywheel and such that's on the other motor now. So I hit the net and before long I know my fear will come true. It is a Gen 5, 454. Or it totally useless to me for what I need to do 454. The sad thing is this is a complete motor from clutch fan to driveshaft yoke. At this point I would trade the whole thing for a clean Gen 4 block.

So at the moment I'm a little perplexed and kind of stuck in a rut. For most, a few days would be no big deal but to me it’s a life time. Not that I'm in a hurry or anything and my wallet sure could use a brake. It’s just I have no plan at all.

That’s not like me.

I walk in complete stranger’s houses (I was a flooring installer for a long time) and in my mind, if not out loud I would already be making major changes to their home. Over the years I had quite a few do exactly what I said to do. In a 5 minute conversation visiting my sister in Maine while we were on vacation I change the whole design of their first floor. They were under construction updating their 40 year old house when we got there and after showing the work in progress and BS’ing with the contractor I started blurting out ideas. The next time we visited the house it had major changes and was just how I said I would do it in that 5 minute conversation. It’s like a natural instinct for me and it not just houses. I see a car or boat and BAM! This is what I would do and then think it out on how to do it.

I do know what the goal is here but what is the right route to get there is the real question. The motor stuff is a mess. I thought a fresh up kit in each of them and it was done. Now I've got three motors and maybe have one out of the three in so-so running condition. The garage is packed with the motors. No space for covers and such . Painting is going to require an insane amount of sanding and I really don't want to start that in August. That’s more like a fall project. The inside needs to be painted also, before or after the outside? I also have no clue what holes in the transom stay and what goes. Ferd has the parts and I don't have the room anyway so in a way it’s a good thing but I need them to know. The gas tanks should happen first but that’s some big bucks, especially after the last couple months. I'm not even sure on painting now or next spring. I like the idea having it hardening up for a few months before I start installing things but………it goes thru it’s first winter before it ever seen.

And last is the parts that have to be bought. I'm building the 454’s (what I like to refer as “the twins”) just like the second to last build I did to the 454 in the 19. It was a good build and a lot cheaper then the last. To be honest if I had to do the last over again I would probably skip it and save the money. But even the cheap build is not cheap. Selling off all my extra 454 parts was also not the smartest thing. Then there is the helm. It has to be nice. That’s what people see. I'm lucky enough that the boat is 40 years old and I will have a lot of options to get the right look.

And it goes on and on and I'm feeling a little overwhelmed. I think I need kick back, buy some hinges and see where that takes me. But what kind?

____________________________________________________________________

The Start

The Start

I had to think about it but the gas tanks are staying. They look a little rough on the outside but it is just light cosmetic stuff. A look inside is like looking back in time. For the 30% of each one I could see they looked perfect. Good thing to. They are part of the boat. I mean they are not just built in they are part of the boat. They are custom built to follow all the contours of the boat. Sides, bottom even inside of the outboard stringers. They are some sort of steel and then are wrapped in glass, plywood and then more glass and gel. At some point before anything happened to them someone put pipe plugs in all the fittings and sealed them up tight. I've got a little crud to get out from taking the plugs out but that should be easy enough.

I've started other things. For the longest time I was lost but I'm starting to get a feel for this project. I built the missing center piece of what Brownie called the “fish press”. Got the dash all bolted up to the hull. I also got the front door’s frame a installed. Now I just need hinges for all the doors/hatches and a boat load of SS nuts, bolts and screws. I need to figure some sort of venting. The back will be fine it’s just the front motor. Usually I'm filling in holes. This time there is none and its up to me to make it look good, look right and work so that’s still up in the air.

____________________________________________________________________

8/16/09

Started sanding the deck today. Along with a little glass and bondo. There isn't much to do but there is a lot of it. At least it doesn't look like someone shot it with a shotgun like the Monza. They left a few screws in the hull and then bondo’ed over them. I hate when someone does that. A heat/cool cycle over a year the screws always loosen up and then you end up with something that looks like a drywall “nail pop” so a couple of them and the deck is done. Around the fish press is a different story. About 12 hole/screws to fill there. This time, for the screws that had to go back I drilled the old screws out and then installed new screws coated with marine epoxy. Then new glass and then a coat of bondo. I'm trying to wait on the hinges I just bought so I can get the doors and covers screwed in so I will know if anything needs any alterations before I do the final fix on them.

So it has begun. The first thing I need to know is how does the fish press doors lock down? Brownie just screwed then down. I want them to open.

____________________________________________________________________

8/18/09

I have found that one of the most expensive things about putting a boat back together is all the missing screws and bolts. You look at it and think there’s only a couple missing from the rub rail not taking into account that there is over a hundred in the RR. A few here and a couple there ad up quick. The next thing you notice is every time you are at HD you are picking up more screws. You don't even have a reason to but you know you will use them. This time I'm trying to do it smart and buy bulk off the net. The first shipment came in today. A hundred thru bolts and nuts and a hundred screws. Lets see how they last. I need 40 thru bolts and nuts just for the hinges and I'm sure at least as many screws are missing from the rub rail and that’s just getting started.

Being I'm still waiting on parts for the Monza I decided to attack the hull and get it ready for paint ASAP. I figure that in the next couple weeks just before the leaves start to fall will be the best time to paint it. The air will be dryer for spraying and then it will have all winter to harden up. Also the thought that its sitting waiting to be put together is all good.

So the last few days I've been sanding, priming, puttying, glassing my brains out. To get the stripe off is requiring a sanding disk of 60 grit. I'm doing my best to get a couple layers of paint off and still leave one on. Not to easy.

Now it’s starting to look like the race boat.

____________________________________________________________________

8/22/09

It’s Friday and raining. I did get a chance to go down both sides with 150 sandpaper. They are starting to look a lot better. I'm hoping for better weather tomorrow but it’s not looking good. I only need about 14 to 16 more hours in it and it would be ready for paint. Next weekend is a holiday weekend and no better time to paint it but I just need the weather to hold off for just a little bit.

____________________________________________________________________

Paint

Paint

8/30/09

I don't know what happened with the camera in this picture. Must have got rain on the lens or something.

But this is probably the first time since the ad "Soul Deep" was made 35+ years ago that a 19 is sitting next to a 24.

Well if I'm moving the 24 over to the grass it time for something to happen. What got me to this point? 15 days of repairs and sanding and fixing and sanding. I could have spent the whole winter on it and not been done. I then realized that I was trying to make something perfect that never was and I had to except it that way. So I pulled the rub rail off and it’s 1000 screws and from there “it was on.”

The next thing was the seat bolster. It was just to high. I'm not very tall to start with and standing in it had my shoulders pinned inside. Not a comfortable way to drive. I also want to add a swing down bottom so you have the option of sitting or standing. When not in use it will swing down and just look like a upholstered fire wall to keep that authentic look. With the bolster to high you couldn't even see side to side if you were sitting. After dropping it seven inches in height it’s all good. Now to decide if I'm going to upholster it or not and in what color?

A couple trash cans and a 20’ extension latter makes a good bench. Add in a couple saw horses and you got enough to hold up everything.

Over the last few days I had to make a motor cover support. I ended up getting a Fur 4X4 and wrapped the whole thing in fiberglass and then bondo’ed it up real good. Add in a couple coats of primer and that was done after 8 hours labor. That was the final thing that to needed to be built before paint. At least I hope so.

The rain stopped about 8am this morning and I was up and ready to go. I figured I would get a chance to do some of the underside and inside stuff just to get it out of the way today. They were not calling for the best weather today and if it rained on it would be no big deal to fix. By the time I finished up the first coat the sun was out and I thought I might as well try to get a first coat on. One thing lead to another and as the day got better and better everything ended up getting 4 coats. I was having a hell of a time with this paint job. The boat is a lot bigger then I normally paint and the worst thing is I couldn't see it going on. I was humid most of the day (maybe a little to humid). So like I said I got 4 coats on everything and it’s a good thing to being I'm going to have to color sand. Not by much but I have to get the blotchy look out of it before the decals go on it.

By the time I took this picture it was 9pm (the camera is on night setting). It’s dark except for the lights I rigged up. I finished the boat deck about an hour and a half ago and the things sitting on the bench about 20 minutes ago. The paint I'm using is dry to the touch and ready to redcoat in 20 minutes but takes a full hour to cure. This picture is taken about 10 minutes before it rained for about an hour. I'm not sure what I will find tomorrow. I hope it’s not to bad.

I hope it looks this good.

____________________________________________________________________

Post Paint

Post Paint

8/31/2009

Rain spots ended up on everything horizontal at the time. Spent most of the last couple days wet, color sanding and compounding. 98% of the water spots are gone and I haven't waxed yet. I have my fingers crossed. I don't have the money for another 2 gallons of paint and activator let alone another 12 hours of spraying. Not making excuses but the brand new sprayer is a POS and never worked right and this is a big boat. The paint was already setting up before I could get a whole area done and then the bugs came. So the paint is not the best job I've ever done and there's some work to do but there is enough on it to work with. That’s what 1000 grit sandpaper and compound is for, working the bugs out. I'll fix it.

Real men can sew.

Fitting for the side panels.

____________________________________________________________________

9/3/2009

Not that I have run out of things to do and I'm definitely not this far along but this was something that needed to be over and done with. It took up to much garage space, couldn't sit it outside and I have to get the seat bolster back in before I can get the rear motor cover installed (they kind of go together).

So off to the vinyl store. I was thinking a 50's couch or a bowling shoe when I picked this out. I think it will work though.

And finally I did something today that made it official.

____________________________________________________________________

The Race Is On

The Race Is On

9/17/09

It seems a little early to be thinking about winter but it’s coming. I figure I have about 30 days until it starts getting to where I will only want to go outside to work here and there. Once they set the clocks back it’s about over anyway.

There's also a little thing that’s called a life. Randy won tickets to go see Alice Copper and meet him back stage again. Not passing on that but it will kill a weekend. Then there is the stuff around the house that will need to be done before it gets bad. Add in there is a 19’ Monza (with a *&^$# blown up motor) and a little Nova to put away yet time is running out.

So it’s a race. What can go back on, in or just out of the garage, it’s going.

The real fight has been the weather. It not all that bad for early fall but for the last week I've been trying to get the inside painted and it has rained a little every day and some how it always ends up in the boat. Until I get the rub rail installed I cant use the new top to keep it dry. I'm not ripping it on a rough edge before it's a month old.

I picked up a bunch of paint off the Oooops rack at the Home Depot. About 50 bucks invested and a crap load of time and the whole inside has been painted. Some places have been done many time as the rain washes it away. The paint is a one part epoxy and should hold up well if it gets a chance to dry. If not I have another gallon or two left for touch up. It’s whole lot brighter and cleaner inside after collecting cob webs for the last 25 years.

With the inside paint done it was official, I can start putting it back together.

One night over that last couple weeks (it's all a blur) I went to Ferd’s just to pick up a couple things.

"A couple thing" turned out to be a vee drive box, prop shaft , prop, rudder (massive, maybe 40 lbs), two motor drive shafts (1 missing a piece where it bolts the transmission), Vee drive mounting bracket, many parts of motor mounts and shaft's guards, Rudder box, couple massive strainers, 10,000 little parts and then there is these……

So with a truck full of stuff and the garage already packed I had to start getting weird things done like the trim tabs and motor and V drive mounts painted of all things first.

I'm also in the process of getting the rudder back on even though I cant put the rudder it's self back on. Ferd still cant find the prop shaft strut and it’s not a “off the shelf strut.” It’s never simple. I'm also having some issues finding a gear that has a broke tooth in the V drive. With the gear a simple gasket set could have it back together and back in the boat but no gear….

All these get installed somewhere and there is a couple others in the garage yet.

In the process of this madness I am trying to sorting out what was a pile of, “I don't know what it is".

After power washing and painting everything I'm thinking just installing the obvious pieces gets them out of the way. It’s like putting the outside edges of a jigsaw puzzle together first just to get them off the board. With them gone I'm starting to figure out the rest. Some I'm going to have to pass on because it wont work with the 454 MerCruisers I have now with out altering the water pump pick up and pulley and probably the ALT also. This will be the first Mercruiser that has everything (pulleys, mounts, brackets, etc) the way it should be on a motor. After piecing a 454 together before I'm not changing these two.

Luckily there is an option. Off Shore Motor Mounts. But that will come much later.

A coat of paint changes everything.

So the past week has been full of touch up painting, rocker tabs, steering, hatch hinges, rub rail and it's 150+ screws (I lost count). Anything to empty the garage.

I normally wouldn't do it this way but there’s no reason that this stuff cant go back if it's ready. That and I wont have to do it this spring!

The best thing of it all is, I think I can be ready to shut down outside operations before the weather forces me to.

It's hinged but I haven't figured out how to hold it up yet.

The start of the dash.

A little hard to see but wow!

____________________________________________________________________

9/30/2009

It’s only the end of Sept but weather change is already telling me it’s time to start wrapping some things up.

As normal everything is happening at once. Not in any order unless you count insanity as order.

Just to get the stuff off of sitting on a pallet in the driveway I first got all the pieces semi put together I could. Being I've started putting the boat together and this is one of the first pieces that needs to go in before anything else I got out the tools and had at it. I cheated a little bit. Before painting it I marked off the side the V Drive left an imprint on before. After painting, part of the plate was still together and as for the rest, after putting it in the boat with the holes in the stringers it was kind of self explanatory. I then realized I needed a couple missing bolts. About half were there so off to Home Depot I go. I wasn't using Stainless Steel this time. I knew they were way to much money before I left the house. Galvanized will be good enough for something that sits under a deck and I know they are strong enough. 6 have been holding my out drive on the 19 for 10 years. This one plate has 12 bigger bolts then it does. The drive plate is not going anywhere. But something that was going somewhere was my damn money. 40 bucks in nuts, bolts and washers and like I said, half were already there.

It's a Hoss and the blue paint really cleaned things up.

I put the front vents in.

Surprise! They are not clam vents.

I know, I know, not original.

They are low profile vents and should pick up more air then the one clam vent that was there before and not be as noticed. I would love for everything to be original but it’s long past that stage. And honestly, I would rather not have a plywood deck or a plywood dash just hinged together either so the changes or “updates” as I like to call them are nothing unusual with race cars or boats and need to be done from time to time. These should work much better and they only vent the very bow anyway. Just like with a inboard around here where the water could be 20 feet deep and 2 seconds later be 3 feet deep, this boat will have a in dash, high speed, depth finder (HawkEye). You wasn't getting that in 1969 either.

In the same breath. I did score a couple things along that same theme.

One is a whole steering set up. Ready to bolt in. At the moment it’s a back up system for what I would like to do. I have the bezel for dual cable steering. If I can pick up the cables cheap enough I'm going to use it and a couple parts off of this. If not like I said, it’s ready to go and always can go in the 19 if I don't use it at all.

The other is a dual controller and get this, it has trim tab thumb control on one of the lever handles. Brand new in the box and the both of them together cost less the 150 bucks.

Besides that I just been plugging away at the little things I can do. I'm running out of time for anything major and to be honest, the money to. I never expected to be this far along and it's awesome but at the same time I have out run my supply line. There is some big things left to do but for the most part there needs to be major prep work before it can be. I have nothing in the way of electrics except gages to lay out wiring and such. I'm not guessing. It’s got to be installed before I commit to cutting a hole or something. Same goes with the rear exhaust and a few other things like motors and V Drives ...... So they sit. I did get some pieces of railing from Randy. I'm still waiting on one piece to come in the mail I had to order and rails on the sides of the cockpit are ready to be installed. I kind of get the feeling that it will probably be the last thing that happens outside but then it's on to phase 2.

Two things will have me bent over the winter that I wish I could have solved.

Gas tanks and the V Drive. I'm trying but just not having any luck.

____________________________________________________________________

Direction

Direction

This is the one and only "Bling Bling" things I planned on buying over the winter for the race boat. Everything else is function before bling. But as usual it just happened to come up last week. Ferd has the original compass’s and spent $600.00 to have them fixed so you can imagine what he wants for them. I bet I could get them for 600.00 but damn! So he gave me a broken Ritchie SS5000 to get me started. It’s the same size and looks so I had to get this one fixed and find another to match. A Ritchie SS5000 is no car compass I would soon find out. The lowest price I ever found one over the last few months was $475.00 + shipping. No chump change for sure. So as I am doing the big list on eBay the other night like every night I get a hit. Long story short it came home for a little less then half of the most of them sell for. Excited would be a an understatement.

I have no clue what I'm doing.

Now to get the other one fixed.

I get a hold of Ritchie and order the new rubber diaphragm and for 18 bucks I have everything I need to give it an attempt to put it back together.

My hands were stained from cleaning out the old diaphragm’s melted rubber for days and I was wearing latex gloves while I did it. Got everything back together and started filling with a home made get up and then I ran out of Mineral spirits. 11pm there was not much I could do then. So on to day two. Then 3, then 4. It took another 3 days to get the last bubble out. No matter what I did. I sucked the air out with a syringe. I over filled it to the point mineral spirits was shooting in the air like a geyser as I stuffed the plug screw back in. I finally decided fill it as much as I could, put the plug in and freeze the whole compass for 2 days. Cold condenses the mineral spirits. Once it was cold enough I pulled the fill screw out, gave it a second shot of room temp mineral sprits and it sucked in the new fluid like a vacuum. Filled the fill screw area and stuck the screw in before the bubble disappeared. It's room temp now and no air.

It's a shame that the card faded over the years. I guess it was from being dry but what the hell for the cost of a $18.00 seal and a can of mineral spirits I can live with the faded card.

____________________________________________________________________

Phase II

Phase II

10/21/09 - My 454 Hell

Things are shifting when they are not stopped in a few ways but they had to be for many reasons. The first is the weather turned on a dime and it rained for 10 days and then we had record day time and night time lows temps. So the outside work stopped and it was about time anyway. I'm running out of things to do. I need a couple more days to finish up some things but there is nothing that cant wait until spring or a Indian summer if we get one.

The V drive and all the parts I could get together has been shipped off to Scott in Florida. He is going to try to get it put back together. I don't know what I would do without folks like him. He has bailed me out of critical issues in the past and this one is life or death. This V drive has to be fixed. It’s not like you can go to the local V drive shop and pick one up. Total custom craziness that has to go back. Without it there is no go. It feels like a 200lb rock has been lifted off my shoulders.

The next thing is I've started on the motors. The bad 454 is taken apart and I know what I need. Now the fun part is I need to find the parts. Things are not popping up like they normally do for some reason. I need a block for a Gen V 454 to get the party started and everything I find people want stupid money for and they are not selling but the prices still stay high. At the same time I am shopping my brains out trying to find what is needed to complete the boat. When the time comes to install these things I'm sure there will be an expense that goes with it so anything I can get between now and next spring will make it easier come install time.

____________________________________________________________________

11/7/2009

It’s funny how I always get a hard time about doing boat work non stop no matter what the weather is like. Take now for an example. Here I am starting the motor builds and it’s November. I've got plenty of time, what’s the hurry? I tell you what the hurry is. I just spent the last 3 to 4 weeks hunting parts and about nothing else. It’s a 454 thing.

Beside the occasional eBay find or trip to Randy’s to scavenge parts it’s all been 454.

This is the reverse rotation 454. The one that makes all this work. It’s also the one with the broken block.

Long story short. One of the motors of the "454 Twins" is a Gen 4 and the other (reverse rotation) is a Gen 5. The Gen 5 of the 2 was the one with the broken block. The guy I bought them from sent me a whole Gen 5 truck motor to make up for the broken block. So now I'm going to use it to have a match set of Gen 5's. I would have liked to go Mark 4's but that would have meant starting a motor from scratch and I still would have had two motors in the garage left over. So I had to go the Gen 5's. They're fill in motors anyway and should be good for the long haul.

So the first thing to do is find a Gen V block. Two and a half weeks later I make a deal and get one home. Cost more then it should but it had to be done. I'm at a stand still with out it.

So now what to do? At first I was going to just put it back together but I thought that I had to try to do some upgrades. This is the motor to do it to if I'm going to do it. It will be a whole lot easier to match it with a normal rotation motor to it then vise versa.

Being I had time I spent some time on the block and crank. I have a habit of every time I build a motor for the first time I always spend a few hours with some files and a grinder. I'm going to paint again and have the tools so why not. I remove all the casting extras inside and out. I know it’s very little in the great scheme of things and for that matter this block was a lot better then some I have seen in the past. Inside it just needed a little fine tuning over the cam and outside was just 2 casting marks.

Then came the crank. It was in sad shape. Casting marks bad! I didn't knife edge it or anything but I did clean it up a lot. Lots of over hang crap. So much so that I am kind of shocked it got past inspection. It looked like they knocked off the mold with a hammer, ground the journals and that was it.

I also got the pistons get cleaned up and Saturday I will put the bottom end together. Then the cam wait begins. I found a guy that will custom grind it for around $200.00 but a hurry he is not.

I cant put the oil pan on until I can get the timing chain cover on. Just the way this motor goes back together to stop oil pan leaks. So after the oil pump install that I had the “pick up” welded on during lunch today, I will all have to come to a stop again. I do have a set of heads to rebuild but I'm going to need valve springs and I cant get them until the cam is picked so again I'm at a stop.

____________________________________________________________________

11/24/09

Ran out of parts.

I gave up on the cam. There is not a billet to be found to make it. If the cam I have is the cam I think it is it should O.K. I hope it’s a upgraded Merc cam. After a couple measurements I think it may be but I'm not saying anything until it's rolling on the waves.

Rocker studs finally came in yesterday, roller rockers are on back order, haven't found a intake yet. I did score a factory rebuilt 750 Edelbrock (#1410 marine) on ebay for $130.00. That's about a third of normal cost. It also matches the one that is in the Monza now. It's already getting a motor swap so it can also use one of the 2 rebuilt carburetors left over from the 24 and I can use the matched set of 750's in the raceboat.

Everything I have is installed. Now it sits until stuff shows up.

And now for this POS!

While I am waiting on parts, that in some cases I haven't even bought yet it was time to see what was going on with motor # 2.

Just to keep folks straight, I bought two motors from a, a ………….lets just leave that blank and say “guy” this past summer. They were supposed to be Mark IV, 454’s. One counter rotating and one normal “drop in ready” and “rebuilt and run just for break in” motors. Long story short they were, one Gen V, one Mark IV 454's. The Gen V had a broken block and manifolds. If you have ever seen when water gets inside a motor you know it’s not pretty. When they ran the motors the one and only time they didn't take the block drains out and let it sit all winter in NC. They don't have major freezes but they have enough to turn a new motor to junk. Lucky enough they did pull the drains in the other motor so all is good there so far. So I'm pissed about having to mismatched motor to begin with. Add in they are all broke to hell, this guy sends me this replacement motor for the block. So to make a set I decide to build two Gen V motors and used the stuff off of the Mark IV motor on it so they will match.

I mean this is supposed to be the replacement motor and it didn't look bad on the outside. It’s didn't have water in the oil and still had some water in it so I let it sit until I was ready. You have to remember I have very limited space and until the one behind it was done it had to stay together.

So it starts and the first thing I notice is the 8qt oil pan off of the Mark IV will not work on the Gen V. I was going to use the it but it doesn't fit right and to whip out the cut off wheel and take a chance on if it would work or not is not in the cards for me. To much money to risk. So I had to buy one for it. I kind of feel good about how much I got it for even though it is a fortune. They normally run in the 3 to 4 hundred range (ya, for a stamp steel oil pan ). So I guess you can say it was only a half price, unexpected, expense.

I open up the motor #2 and for the most part it looked awesome. Just a couple bad spots but as I started to hone out the cylinders the bad spots were not going away. It was where the pistons sat at with water in the cylinders. Ya, I said water in the cylinders. The other motor had lots of water damage and yet this one should have had none. Hell it’s the replacement block for the bad one but the motor was left out in the rain without a cover over the carb. Had water in the cylinders that sat for who knows how long.

It’s just 2 cylinders.#3 and #6. #6 is passable. #3 not so much and it’s the one that also looks like it has a crack. Ya I said “crack”. After doing some serious honing of the bad cylinders it looks like I may have found a crack below the piston stroke but still in the water jacket area. I'm not taking the risk so off to the machine shop for pressure testing and to see how much the cylinders need to be cut by.

What pisses me off the most is I wanted both motors the same. Not much chance of that happening now.

Not a good picture for what I am supposed to be doing right about now.

____________________________________________________________________

Winter

Winter

11/25/2009

The shop called. The block is good just needs to be bored out to fix it. More money but it has to be right. I know I will be paying for it for years to come. At this point I might as well go to the end.

And then I was working on the second head for the second motor and look what I found. That’s not a hair across that bolt hole.

Then with nothing else to do I got another kick in the balls when I took the Mark IV, 454 apart to get some of the pieces I need to build the Gen V, 454. Besides some surface rust (the reason this one will need to be taken apart) this motor is brand new. I mean so new that there’s still molly lube around the lifters. Everything is still shinny. It’s a 4 bolt main and has new pistons, rods, a knife edged crank, double roller timing chain, the heads are clean enough to eat off of. Just enough to piss you off. It‘s all slated to go in the Monza and yet the bottom end of this motor is nicer then what I have in the 19.

After a little thought I want the bottom end for the 19. I cant just let this one go in a boat that I am going to sell. A 4 bolt 454 is worth it's weight in gold.

Another nice surprise is the 30 over pistons and rods out of the Mark IV will fit right in the race boats motor. I need domed .210 pistons for the Nova 19 and they are just flat tops so I'm going to use the whole set of rod and pistons in the Gen V and the rods that came out of the Gen V block will get the new pistons. That's if I don't find a nicer set of rods for the Nova in the time I start it.

____________________________________________________________________

12/8/09

Well guess what? I have to take the 1st motor apart again. Not the motor it’s self but I do have to get the fly wheel off of it. I have been going round and round about this BS and it has come to a head and has to be put to bed.

After talking to a couple folks over at Donzi the other month I was convinced that there was no difference in the Mark IV flywheel and the Gen 5 and 6, 454’s. Now I am convinced that there is a difference. Extensive searches came up with a thread on OSO of all places from years ago. The guy had the same crank (matching #s) and flywheel combo that I have now and it caused his motor to vibrate insanely. And as I looked deeper and deeper all the experts say not to do mix the two flywheels but no one says why or what the difference is. I intend to find out and put it in print. I figure it’s just a weight difference but no one saying is enough to piss you off. The damn things look the same.

I have a flex plate off of the motor I got with the tranny still attached. I also have a balancer that House of Balance that will match the Mark IV flywheel to it. So now I am into custom flywheels. It’s better them buying or trying to buy new. 250 bucks to start to get one for a inboard (the ring gear is on the outside) and I haven't found one for a Gen V yet after a couple days.

As for the motors themselves, missing this, missing that. Before this weekend (he says with his fingers crossed) there should be a head (replacement for the broke one), an Endelbrock Air gap intake (one down, ½ price from Craig’s list), SS Roller Rockers (got sick of waiting on the first guy's Back Order excuse) and an oil filter bypass for a Gen V (so I can hook all the existing oil cooler and remote filter lines to). Last, I may have the flywheel back also. All for “ready to drop in” motors.

Then I can start to figure out the motor mounts.

____________________________________________________________________

12/11/09

I just picked up the Gen V flywheel from the balancer’s. Yes there is difference. Just a few ounces on the opposite site of the counter weight but with it still on the flywheel, double that weight would have been on the wrong side and it would have shook like a SOB.

I'm kind of happy they did find a difference but that means that I'll have to take the 1st motor apart again. Not that I want to but it’s a whole lot better doing it in the garage than taking them apart after they had been set in the boat.

I don't know if it’s bad luck that they have to be rebalanced or good luck that I found it but either way, in the end it’s all good.

The head is in and almost ready to put back together, I pick up the roller rocker today from UPS, the one Craig’s list intake came in yesterday along with the oil filter bypass. I think I may be able to finish one this weekend (oddly enough it is the second one) and the other should be done next. If I can find another intake.

____________________________________________________________________

11/13/2009

Busy, busy, busy. In what seems to be never ending. When I bought the boat one of the reason was it was pretty much all together. Well, your eyes can deceive you. It seems like I have a never ending list of things still to do and we are into December already.

Rigging the boat is going to be a chore to say the least.

I'm still not settled on steering yet. I have one set up but I would rather do what I have the most of (old school dual cable) but I still need two cables and some other pieces to complete it. Steering cables are not cheap and their not on the top of the big list either.

No word on the V drive yet (no news is good news….I hope). I would have though Scott had his hand full with it and it was tiny compared to everything else that was going on in his life.

The motors……..I leave that to the other thread.

Just picked up two tachs last night and that should be the end of the gages but that is just the start of the electric.

Wiring…….I'm taking donations. There will be miles of it and for the most part I am using what I used in the 19. Right off the HD shelf. Almost 10 years and not a single issue with any of it. I really need a source for the heavier wire though. Like what comes off the ALT to the key and back.

The decals are on hold for another week. Not that I could install them anyway but the wait is killing me. Just want it off the list. Also still waiting on the “right” flag. I guess I need to send another email.

Gas tanks…….nothing. Still looking nightly.

I need to come up with some sort of door/hood supports. I have enough gas struts I could lift the boat up and down with them but they just don't look right on the boat. I'm thinking something like a car hood support. The fold down metal sticks??

____________________________________________________________________

12/14/2009

The second motor is done for the most part. Nothing more goes on it until it's in the boat.

This is the first. Again.

The tail is taken off and the flywheel is in the truck to be dropped off tomorrow. Now that is back up on the stand I'm going to finish it up and change a thing or two that I discovered when doing the second.

To be continued.

____________________________________________________________________

12/24/2009

2 down (still waiting on one intake) and one to go for Christmas.

I'm starting #3, 454 today but that will have to be another page being it is for the 19.

Not sure what I am going to doing with the build yet. I have and had lots of ideas over the years and I have a lot of stuff.

____________________________________________________________________

Looks like it's getting to be to much for just one page.

____________________________________________________________________

More to come!

____________________________________________________________________

The SuperNova19 Network