My Super Nova 19

THE EARLY YEARS

Time Warp

____________________________________________________________________

FROM ALLEY 201

2000

2001

2002

2003

2004

2005

2006

2007

&

- THE NEW SHANTY TOWN -

2008

2009

2010

2011

2012

2013

2014

2015

2016

2017

2018 / 2019

____________________________________________________________________

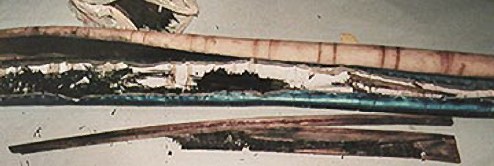

Original builds of what makes it go.

JUST CLICK THE LINKS.

____________________________________________________________________

-Where To Start?-

I started this page in 2003/2004.

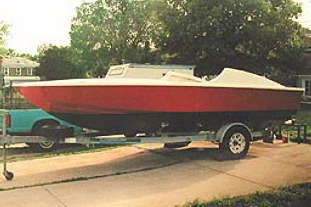

I've had the boat for a couple years prior to all this and been through enough stuff with it already to fill a scrapbook (and I have to prove it, that's why I started this site) but let me see if I can catch you up on what's going on.

I'm sure you can tell I kind of like my 1972 John Allmand, Super Nova 19 to say it mildly. I guess you can say this is my section to laugh, cry, vent and brag about my boat. There is a little of everything of what I have run across since I have owned it.

I will be totally honest too. There has been many times I wish I would have never found this boat. One day it even came to me standing in the driveway next to it with a 5 gallon gas can in one hand and a road flare in the other. I think the only thing that stopped me was when I thought of the lost history if I did burn it. I swear though if you would have drove by with a trailer hitch on your truck that day you could have took the boat with you for free.

Then add in some of my stupidly along the way and it has been a wild and fun ride.

No matter how bad things get everything changes when you hit the key and put it in gear (as long as it all works). After many seasons every time I start the motor, it still gives me chills up my spine and I am not just saying that. So here we go.............

____________________________________________________________________

Why

Why

Summer of 2000 I was at a cross roads with the boat I had at the time. It was a 1973 18' Larson Veloro Sport with a hopped up Ford 351W / Mercruiser drive package in it. Pretty fast but not an impressive boat to say the least. I used to describe it as the "fastest Pinto on the bay" but I had way to much time, effort and money into the "Pinto" to let it go. I always wanted something better but it was never practical at the time but then the decision was made for me by an under water object.

I hit "it" at about 45 mph. I was in the channel with about 40 feet of water under me at the time "it" happened. I never did see what "it" was. At that point I was more concerned with getting back to the boat ramp without sinking then I was looking for "it". For the last quarter of the trip back most everything was under water including the batteries. Don't ask me how it all kept running. When I did make it back it then took twenty minutes to drag the boat on the trailer up the ramp while water poured out. The old Chevy truck wasn't into pulling a small swimming pool up a slick hill.

The hull was trashed. Three rips 5 to 6 feet long down the port side. The only thing that kept it afloat was the foam inside. Not wanting to put that much time, money and effort into it again to fix the "Pinto" it was time for a change.

I figured I still would have everything from the Larson so all I would need was a cheap hull and just swap it all out.

Well that's what I thought anyway.

Hull #1941 or the 41st built.

____________________________________________________________________

The Find

The Find

After all the dust setteled it wasgetting close to fall and starting to get cold. The perfect time to buy a boat. Now the way I would always go about looking for a salvage boat was cruising the local papers and water front neighborhoods looking for a boat that the owner obviously didn't want anymore. You know the type that looks like it hasn't moved in a "few" years. It is amazing what people will "unload" there once loved boat for if you knock on the door at the right time of year.

After a couple weeks of that with no luck I thought I should try looking for a boat on the Internet. Back then my dinosaur PC was just something to decorate my desk. That thing crashed more times then it worked and surfing the net was just a pain. Not finding anything in my area I wanted to buy though I would have to suffer through.

In one of my searches I ran across a company called bentboat.com

With a name like that I had to look. On there site was a list of insurance salvage boats sold thru eBay. Now the company was in Seattle, Washington and the boats came from all over the country. Never making an Internet buy before this was very strange. Buying things by a picture and a description only. No first hand look to see what you are buying.

Then I saw a listing for a boat in Copiaque, NY. Thinking that was only about 150 miles from my wife's parents house, it was possible to get it but it would have to be worth it.

I clicked the listing. "Well what is this?"

As I started looking through the page and pictures I knew I had to have it! Remember, I used the Internet back then about once a week, if that, and never bought anything on-line.

The prices Bent Boats auctions went for in the past was very cheap (also eBay was kind of new) added to the interest. This had to be scam. I then checked out eBay and Bent Boats and found them to be O.K. But I didn't trust anything and I couldn't look at the boat because I live in Maryland.

Boy this buy goes against everything I lived by up to that point. No on site check out, company hosting the auction from Washington state, the boat was in New York, I live in Maryland, eBay, never bought anything on the Internet before but I still had to have it!

Then everything just fell together perfectly. It was like a higher power wanted me to have it. Like I said, moms was close for a sleep over. I had a trailer (it didn't come with one), I had the money (well... to a point, it was an auction) and the auction ended on a Saturday morning. I had to try and made a bid of $1000.00. The auction sat at $400.00 till the last 2 minuets then it jumped to 600, 650, 700,750,775,800, 825 (that is how I learned what auction sniping was the hard way) and then time ran out.

Wow!

I was white as a ghost until it was over but I won!

What a start!

____________________________________________________________________

Time To Go Get It.

September 27 2000

After the excitement of the auction the reality and horror of what I just did set in. What if I get ripped off? What if the boat should have been scraped instead of sold? Are ALLMAND boats junk and that is why I never herd of them?

I will find out soon enough. It was time to go get it.

The trip up was uneventful. Everything went fine until I got to the boat yard. The boat was 8' wide at the transom. My trailer was adjustable but my adjustments were limited in a busy boat yard during hall out season. I did what I could by eye and had them drop it on with the lift.

"This should work" and off we go south bound.

We had a map that we got from MSN maps and we really didn't pay much attention on our way up through New York was all on "Parkways".

No trailers! We made it through with the boat with only some stares from other drivers and using both lanes when going under the those low bridges. Got to moms and when I looked at the boat I realized it was coming off the trailer. Maybe that's why I got some of those stares on the Parkway?

With what daylight was left my main concern at that time was to get it right on the trailer. The next day it was going to Maryland in back of the van that will have my new 6 month old daughter Sarah in it . While I got it straight on the trailer I looked the boat over better then I had time to do before. In the boat yard it was a quick look over to satisfy myself it was worth the money and then getting it set on the trailer. As I looked there was nothing but smiles on my face. The seller was very honest representing the boat in the auction. Most sellers try to be honest but it is the stuff the past owner's doesn't know or are ignorant about that scares me the most. There was problems but the hull is solid as a rock, everywhere! I was ready for bad stringers and transom after the boat sat for so long but there was no need. More and more smiles.

Before I knew it I had it home and got things started.

At moms, just back from New York. Looks can be deceiving.

Outdrive with a bent prop being held up by rope. Three interior colors and all rotten.

____________________________________________________________________

Apart

Apart

The time it took after the auction to get it home and taken apart it was mid November, 2000 and the weather really started to get cold. My plan was to get everything I could taken off the boat and I would redo those pieces in the house over the winter. I don't have a garage in my townhouse so that was my only option. The rest of the boat would have to wait until spring.

When I started taking things off I noticed a few things. First the interior was totally rotten. Both vinyl and wood and did'nt match (3 colors). The outdrive lift was broken. Prop was bent. The motor was frozen but that wasn't that bad. Then two things dawned on me and they weren't good at all. First the motor and drive I planned on taking out of my other boat was not going to work in the new one. The Volvo 270 hole in the transom was to big for a Mercruiser and like I said the transom was solid and I wasn't cutting it up. Also the small block Ford from my other boat was not going to replace the Chrysler that was in the boat now. So now my drive package from my old boat wouldn't work. Oh well, I can work with what I have. I guess.

The second thing was when I was taking things off the boat I noticed so many holes in the hull where past owners had installed stuff and either removed, lost or broke it then just installed new stuff, in new holes. Like there was three sets of snaps screwed into the hull for the top alone. That was over 40 holes to fix by them selves. Then there was a bunch of other stuff that left more holes.

After all that it was time to pull the motor.

When I looked up the motor I found out it was not the original Hollman / Moody 318ci it should have been, it was a remanufactured car motor from the early 1980's. That has to go and out it came.

Now I'm planning on replacing the old 318ci with a 360ci so I took the bell housing and some marine stuff off of the motor and got rid of the rest.

But I will get to that later. It was time to go inside and leave the hull until spring.

____________________________________________________________________

Over The Winter

Over The Winter

Over the winter of 2000 / 2001 I did everything I could. Total new dash board (electronics, gages, switches, etc.) with all new wiring harness for the whole boat. All of the upholstery was redone by me, did I say I do most everything by myself? Rebuilt the outdrive and anything else I could do. So when the weather broke I was going to attack the boat and have it done in a month. Or that's what I thought again. Until then it was time to go back to eBay and other places for parts and wait on spring.

Around late February it got warm for a couple days and off I went to the junkyard for a Mopar 360ci to tear down so I could get it to the machine shop before all the spring time racer folks showed up. I also wanted to send off the heads to a buddy to be reworked and have all the internals balanced. Then it dawned on me? Where is the flywheel??????

Mopar's are externally balanced and it had to go out with the other parts. Then I remember that it went with the old motor.

"Oh well, it cant be to hard to find a new one right?" Another big and major mistake.

A dash board in a bag.

Tearing it apart and all those little holes. A pile of stuff done over the winter.

All the darker spots have to be fixed. Old seats will work until I can afford new.

____________________________________________________________________

Spring Email

Spring Email

Spring 2001 came and that's when the problems began. Well maybe not at first but I still hadn't found a replacement flywheel and I had most of the parts back already from the machine shop. "This could be a problem!"

Oh well, I am still waiting on a couple parts anyway. I will get the hull ready for paint and that is going to be a chore by itself. There were 2" round holes in the bottom of the hull for a speedometer and depth finder senders that didn't look like they worked in 20 years and a couple extra air vents. The boat had more vents then a battleship, a 19' boat doesn't need eight. Then there was all those snaps and etc, holes. That kept me busy for a few weeks. No garage means I was at the mercy of the weather. It took forever but it was done by the end of March. I was going to hold off on painting it till the motor was in. So I stopped there on the hull and moved back to the motor. A couple weeks prior the head guy told me the heads were junk (cracked). He said it was pretty common with junkyard Mopar motors. Again I went on-line and found a set of bare castings for a 360ci for $900.00 delivered. I looked at it as an early upgrade being they were the new "Mopar swirl port heads" but it was also a thing I would have to save up for and that took time.

To keep things going I figured I had to get it painted first. That had to be less money. The problem was no one wanted to do it and we never even talked money. As soon as I said boat the conversation was over. I live in the same county as the Navel Academy so you know there is plenty of boats around. I couldn't figure that one out. After hunting for weeks for a painter with no luck it is now late April and off I go to Home Depot for a paint sprayer (I already had the compressor and hoses). The summer is almost here and I am no where near done. Time to take things into my own hands.

I must say for it being my first time ever spraying anything it didn't turn out to bad. Hell it looked dam good.

Time to put it back together and that went on until mid June.

I got the heads and everything else back for the motor except I still didn't have a flywheel. Now the flywheel became top priority. So on days I had time I would scourer every boat and auto junk yard in the area and at night search the Internet. By then I had bought a new PC and it was a lot easier. This went on for months. I can still find posts that come up when doing a search on a Chrysler to Volvo flywheel three years later. The boat was painted and put back together. The motor was together wrapped in plastic ready to go and I had no way to hook the two together.

Then one day I got an e-mail.

All the primer areas had to be fixed. All new paint.

All of the interior is in but the seats. Put back together but short 1 flywheel.

____________________________________________________________________

Email

Email

Late August, 2001 I got an e-mail from a parts broker out of New York that said he had found the flywheel I was looking for.

This had happened many times before and I even had a couple flywheels delivered just to find out the people didn't know what they were selling.

There was one difference this time though, this e-mail also came with a picture and the flywheel was still hooked to a small block Chrysler.

"I found it!"

I e-mailed back in a flash and the broker emailed back again with a price. "Delivered......$800.00 and I will throw in the bellhousing." That's what I paid for the boat! But what could I do? Just days before I was on the verge of burning it like I described at the top of the page because I thought all the work would have to be done over again and another drive package would go up for sale in the news paper because I couldn't get the Chrysler motor to hook up to a Volvo outdrive.

"Sold", I wrote back to the broker and sent him a check. By the time the check cleared and it shipped it was September 9th 2001. Now don't get me wrong and I know in the grand scheme of things of what happened a couple days later my problem was very small but you can imagine the nightmare of having large, heavy, metal objects shipped through the US mail from the west coast to the east coast around that time. The bellhousing showed up about three weeks later but still no flywheel. I know the flywheel is the right one now because it is the same bellhousing as I already have. The flywheel stayed lost in shipping for another three weeks and then I finally got it after many phone calls and e-mail's. Now it is getting close to November and I still have to get the flywheel balanced. "That's it, I'm done till spring".

Not a good day.

Worked on it until dark and all I had was more work.

____________________________________________________________________

Spring 2002

Spring 2002

It was late March 2002 by the time the weather broke and this year I know I'm ready. I have been shopping on-line all winter for upgrades and other stuff like a high speed depth finder, a good prop (best guess on what size), radio, pop up bow light. Stuff like that. Here I have this list of things to do and the boat hasn't touched the water for years.

First was the motor. I had to get this thing out of the way no matter what! I drop it in and hook everything up nervous the whole time. I built the motor last year. Was it right? Did I forget something? It is my first Mopar small block build.

I got everything done but left the drive off because the suspense was killing me. I dropped a battery in and spun the motor a few times with the coil wire off to prime the it. "Its finally time to make something happen". Coil wire on and contact! Two turns of the starter motor and vaaaarrrooooom. Starts right up and settles down to a nice cool idle. The motor sound strong and smooth. Now if the outdrive works I am all set.

On goes the Volvo 270. Pop it in gear and the prop moves in forward and in reverse. Things are coming together. A couple days of tightening things up and I am ready for a test drive.

Its in and hooked up! I wish you could hear this!

____________________________________________________________________

Test Drive

Test Drive

By now it is late May, 2002 and I am ready to go.

This will be the first time the boat has left the driveway in over a year and a half. Also it hasn't been in the water for more then six years. On my way to the boat ramp I get my first lesson about having a 60 gallon gas tank, I have to stop at the gas station. I drop $50.00 in it and off I go.

I get to the ramp and drop it in. Man! It sits nice in the water. I jump in and fire up the motor. Everything is going great. Put it in reverse and start backing out straight but as I turn I hear a ping, ping, ping. Now I know what bad U-joints sound like and that is not it. When I straighten up it goes away. It dose the same thing in forward.

Dam! What is wrong now?

Oh well its time to break something! I give it gas and no noise, more gas still no noise, WOT and still no noise. I look down and the speedometer is buried. Wow! I back off about half and start to turn back for the ramp. Ping, ping,ping real loud this time.

It quiets down some as I straighten back up but you can still hear it and then it dawns on me. Its the vibration damper bolted to the flywheel.

Oh no! Now I know I have to pull the motor again to fix it. That really sucks but that was a cool ride for as short as it was.

At least this time I have run it. I know I have to pull the motor and there is a few thing that I want to fix but at least I know what I have and if I can get it right it will be pretty cool.

____________________________________________________________________

Pulling It Again

Pulling It Again

After my very short test drive I'm excited and kind of mad at the same time. U-joints are no big deal. Pulling the motor for a vibration damper is a whole other story. I figure while I am at it I might as well redo the bellhousing bearing and seals also. After finding the parts which took a couple weeks and couple more weeks of work I had the motor pulled, damper fixed and back in. Now its late June, 2002 and I am on my way

to the boat ramp again.

I drop it in the water, start it and pull the boat out. With the drive in gear I spin the wheel all the way to both sides. No noise. "Awesome!" It's time to go. Gas, gas, gas and everything is perfect. Then after a half mile driving in a circle, POP and steam starts pouring from under the motor cover. I shut it down and open the hatch. "Where is all this water coming from? All the hoses were intact." Then I realize that I either have cracked the block somehow or I have blown a freeze plug out of the back of the motor. This could not get any worse. The motor would have to come out again!

This day I will take the boat home with my head hung low again.

I was going to miss the 4th of July on the water again this year.

After getting it home I soon found the freeze plug in the bilge and knew what it was. At least it wasn't a broken block. I still couldn't figure out why the freeze plug blew out though. I had pictures of the old motor and the new cooling system was just like it was.

I fixed the freeze plug and to make sure it didn't happen again I JB welded them in place on the back side of the motor. This way if another one blows out I wont have to pull the motor. Got the boat back together and off I went again. This time I road around within view of the ramp for about an hour and everything was fine so it was time to go for a little ride. Just to see how it acted at speed and how the motor would run for a longer period. I was about 8 miles from the ramp, I really wasn't pushing hard and then boom again. Water everywhere and the motor has blown another freeze plug. I quickly pull over to the closest marina but by that time I had already cooked the gaskets in the exhaust manifolds from lack of water.

Now my boat was smoking and I had a long walk to go get my truck and trailer. I call the wife to ask for a ride and then wait for her to come and get me.

While I am milling around the rundown little marina waiting for my ride I look over next to a shed and what do I see? An original (pretty rare) small block Chrysler with all of its original cooling system. Almost like it was fate that I broke down there. Now I know what's wrong. The old motors cooling system that was in my boat before was totally wrong.

After seeing the right way to do it I hunt around for some more parts and pay out some more money. Put the cooling system back the way it should be. Fix the exhaust manifolds and off I go again. This time the boat was perfect but being late August there wasn't much time left to enjoy it.

Another one of the things that went wrong toward the end of the season was the tilt motor for the outdrive burned up and that made launching and retrieving the boat a lot harder on busy days. Winter even came early that year and it seemed like all I did was a lot of shake down cruises anyway. By the time I put it away for the year I already had a list a mile long to prepare for over the winter to be ready for the following spring. At least this year I made progress and it ran fine at the end.

I first figured it would take 6 months to get the boat going. It has now been 26 months and like I said I had a new long list of things to do.

This was just after the first ride where nothing broke. I also met my first couple

of admirers of the boat. The guy on the dock in blue talked my ear off about it and

guy in black chased me down just to check it out.

That's never happened to me before. The ironic thing, he was driving a WellCraft Nova.

I guess good taste runs in the family. Even if it's an extended family.

____________________________________________________________________

Time For The Fun Stuff

Time For The Fun Stuff

Well, as 2002 ends and 2003 begins I start stock piling everything I will need for spring. I find deal after deal on eBay in the middle of winter for the stuff I want.

There wasn't any "must haves" on my list so I could be choosey on what I bought. Boy that is a good feeling for a change. To much money for something? Then wait for the next one, no hurry.

When spring arrived I had a brand new Edelbrock carburetor for $100.00 to install. A new left hand ocean races prop 15 1/2 X21 cupped for $63.00. Boy did that change the way the boat handled. With a right hand prop it drove like a tank at high speed. Both hand on the wheel, pulling hard to make the boat turn. With the left prop the boat drove like it had power steering at any speed. Now if you let go of the steering wheel at any speed the boat just goes in the direction you left it at. I have never had a boat with no steering wheel torque from the outdrive.

I got a Petronix igniter to replace my points distributor with an electronic upgrade. I also picked up a tilt motor for $35.00 Add in a couple cosmetic things and after a couple weeks I am ready for the boating season.

The projects were easy and done soon enough and the rest of the summer and fall were nice. I really didn't have any problems with the boat except the tilt system. That seemed like the only on going summer project. Fix it and something else in it would break. Do it again and something else would break. This went on and on and I got real good raising and lowering the outdrive with just a rope.

After a while I had enough confidence in the boat to go where and when I wanted to. I even did a couple night rides. I was nervous the whole time but I did it. One was the 4th of July on the water.

Finally!

Like any good rebuild project, as the season was coming to an end I started thinking what I was going to do next spring. I had a good boat but now it is time to start thinking on how to make it a great boat. Now is the time to start making plans.

Just resting.

You have to now and then when you are well over 30.

____________________________________________________________________

Making Plans

Making Plans

Over the winter of 2003 / 2004. I finally got the seats that match the rest of the interior and I can get rid of that aqua stripe that doesn't match anything and just looks ugly. Then I get the bright idea of rebuilding the motor with all the upgrades I couldn't afford when I was trying to get the boat together two years ago. I bought a Master re-ring kit with all the bells and whistles. Molly rings, good bearings and such. A Edelbrock degree-able double roller timing chain, a duel plane cam (awesome cam), custom length push rods and roller rockers. A friend told me "If it ain't broke don't fix it" one time and I'm about to learn that lesson the hard way.

The weather broke and I was on the motor work right away. Everything went smooth and I had the motor back in, in no time. It was May and I was ready to go.

Time to see if all these upgrades worked. I run the motor in the driveway and it sounds fine. Down to the boat ramp for a test drive. I didn't go a hundred yards and the motor made a couple clangs and died. I get back home and pull the valve covers to find a bunch of bend push rods and a bent valve that let water get sucked up into the motor. Pull the top end apart and rebuild everything. Nothing was frozen up so there was no reason why it happened. Maybe something hung up for a second and the motor tore itself apart from there. Stuff happens. After a couple weeks I am ready for another ride. Again less then a hundred yards for the pier it dose the same thing except with one exception. The roller rockers are frozen to the rocker shaft. Come to find out C.A.T. Performance had a design flaw with the way the roller rockers oiled themselves. They just didn't work and they broke a lot of stuff to prove it. I got my money back and another $100.00 for my trouble. That didn't even come close to what I had in it to fix the motor after there product screwed up but I took what I could get. I installed the old rockers around late June and enjoyed the rest of the summer. I had tilt problems all summer again until I took a claw hammer to it. End of problem but now no outdrive tilt. I felt kind of "ghetto" with my cool boat and a 2X4 holding up the outdrive but when it was in the water who cares. Then I picked up a new "used" complete tilt system and with my fingers crossed, my problems are solved.

Fall of 2004 after a very "cool" in many ways ride.

Just back from the last ride of the season and the temperature was in the 40's.

____________________________________________________________________

Future Plans

Future Plans

2004/2005 and winter is here again and I really haven't come up with much to do this spring. There is a new CD player, a drop in hidden horn and a few cosmetic things but nothing much. Nothing will be touched on the power plant. I have other plans for it if they work out but I don't plan on even starting that until fall of 2005 at the earliest. I can tell you that it starts with H/M Big Block but that is it for now.

A few things have to come together for that first. Updates will follow as they happen but for now the boat is put away for the winter.

Not much you can do on day like this.

____________________________________________________________________

Spring 2005

Spring 2005

Well the best laid plans worked out this spring for a change. It was what I didn't plan for that nearly ended my boating season before it began.

It all started about mid March. After I was sure the winter freeze was over. I got the boat out of it's hibernation and got started on my "list of stuff to do".

The weather was good and everything was done before I knew it. With nothing else to do I decided that there was just to many places to "touch up" with just touch up paint and it was still very early in the year so what the hell, I am going to re-paint the white paint.

I got started with no problems but I quickly found out I needed to do a couple other things to make the paint right. The first was to replace the glass in the windshield. It has always had a crack in one corners from when I first installed it a couple years back and when I took it out of its frame it cracked all apart. Then the seal between the glass and hull was dry rotted and had shrunk up short of the ends of the glass so it had to be replaced also. The glass and the seal (when I found one) came to about $200.00. Wasn't expecting that but now was the time for it to be done. Add in all the paint supply's and it took a couple weeks (money wise) to get everything together. Just when I thought I was ready is when the weather turned to the second coldest and the wettest spring on record for these parts. Remember I do everything outside. Things moved along at a snails pace except for the wet sanding. Surprisingly doing it in the rain is not as bad as you would think. There was one thing good about the weather holding up the show. I had time to look at the deck and decide to change some things that bothered me from the first time I looked at the boat. The boat originally didn't come with a venting system. In 1972 that was a "after thought". At one point in the boats history someone decided to install one and when they installed the cowls for the vents they were going for function only. They didn't bother with the fact that they didn't look right where or how they were placed. At one time there was three on the bow alone. I took one off and fixed the hole in the deck the first time I restored the boat but needing to vent the boat I left the other two in place. Now it was time to get rid of the them and make a new, proper vent system for the boat before I painted it.

Again things went very slow but they got done until it came time for paint and then they stopped. I couldn't get a dry day to shoot the paint for weeks and when I did I still ended up with a couple wind blown things in it. I cant wait until I get a garage. Life will be so much easier.

It didn't come out to bad over all. When I got it all put back together it looked a lot better then it did before I started so all and all it was worth it and with those cowls off the deck really changed the look of the bow of the boat for the better. More then I could imagine. So it was well worth it in the end.

Much better! No vent cowls, new white paint and windshield.

There is a horn and bow light there if you can find them.

I also had to change two of the rear vents to face forward as part of my venting system overhaul.

I used the lower profile Attwoods cowls to give it a more of a older, racier look.

I have to say I was never really very excited about the paint like I normally should have been. With all the hold ups from the weather it all happened over many weeks instead of days and I also had something else on my mind. Just after I took the boat apart I ran across something on eBay that really got my interest so I bought it and couldn't wait until I got the boat back together and try it out.

What was "it"?

"It" was Stainless Marine, stainless steel, performance exhaust manifolds. The company Allan Brownie Brown works for now. It was like it was meant to be! These things looked sweet and after doing some research on them I knew they would add some speed but I was in for a couple surprises after my first test drive.

I didn't even bothered to wash the boat after putting it back together before I got the manifolds installed with all new plumbing so they would work properly. Started the motor in the driveway and boy did it sound good. It was time to go to the boat ramp. I drop the boat in the water and hit the key. The starter seemed to be struggling to turn the motor over but I figure it was drained battery's. I know they were not charging at idle in the driveway. It fires up and it is time to go. I am going for a quick run to charge the battery and to see if anything shakes loose.

Off I go and it was awesome. The boat picked up 6mph top end, sounded better and ran better all together. I come back to the dock and slowed down. The motor starts to stumble a little but I figure it is from not being run for awhile and it still hasn't reached operating temp.

I shut it down so I can look it over. With a big smile on my face everything looks fine. I go to start the boat again and the motor is hydrolocked. Took a couple minutes to figure it out but it was. That means that the first time I thought it was low battery's it was water in the cylinders that had to pass before the motor turned free. Where did that water go the first time? In my oil. I now have a hydrolocked motor and I just ran wide open (even though it was a short ride) with water in my oil.

I could have died on the spot.

I took the boat home, put the old exhaust on it. I then changed the oil and filter four times in a afternoon. I didn't see any water in the oil the last time so I let it sit for a day or two then ran a "engine clean out" (Diesel fuel in a can) through it and changed the oil again. I have been out for a couple rides since then and it seems like it came through OK. Dodged a bullet that time.

You would think I would be happy that the motor survived and I got my money back from the auction for the manifolds but.... I now know what the weakest link with my set up is and if I had a Chevy it would be a easy fix but I have a Chrysler 360ci. No one make exhaust for these motors anymore except Osco. The big cast iron type. I did find a guy that will make a set for me. They are really nice and I am sure they would be better then the set of Stainless Marine's I tested but the cost is high, like $2200.00 high. For me they are the only option if I want something like that. I went as far as to buy back the bad S/M exhaust manifolds to see if I could cut up and fix them but after taking one apart I found it would require a lot more work then I am able to do. They will have to be striped to the exhaust flanges and then installed all new tube inside and out. If I ever become a welder I may give it a try but until then there is not much I can do. I figure it will only cost half as much to rebuild the Stainless Marine's as it would to buy the new custom set but if the S/M's don't work when I am done I am out the money. The new custom set should last 20 years. Not a lot of money if you think of it over that much time but for this backyarder it may take that long to save up for them. If there is any good welders out there that wants to take on a pet project hit the contact us button. LOL.

For now I am stuck with what I've got!

They were pretty but with all the leaks they "are history".

____________________________________________________________________

Summer Time

Summer Time

Well things have stopped and progressed at the same time. It is mid summer 2005 and the boat has not been in the water in many weeks.

First to the exhaust. After the Stainless Marine / eBay exhaust nightmare I decided to be done with it all and put the old exhaust on the boat and enjoy the summer. I guess between all the installs and removals plus they were very old it didn't take long before problems started. First I blew a (new) water hose. I figured that the manifolds were a little clogged. Before I got to fix it I found them to leaking also and that's when I had enough. Time to make up my mind and now. Either go with new Osco's cast iron and have it fixed or put out the money and enjoy it for years to come. The boat has already voiced its opinion. "Fix me one way or another or I will trash your motor."

After much research I still only came up with one company out of Australia, Victorian Marine Technology. So I bit the bullet and bought them. $2200.00 and 10 days later they were at my house. I haven't installed them yet but I have high expectations. Now to pay for them. It doesn't look like I will have a Christmas or birthday present coming any time soon. The wife says "years". Oh well, I'll just have to take a boat ride on those days and it will be worth it. Well maybe not Christmas, a little cold out, here. I will have to look at old pictures then and dream.

I also bought and installed docking lights off of eBay (I get so much stuff off of there I should have named the boat eBay) like what was installed in the original Novas from Nova Marine. Today's light kits are smaller and at a different angle so when I installed them they didn't go in the exact location as if it came from the factory. They are close enough though that most will never know the difference. I also have a stern light like the old style Nova Marine boats on its way but I am not in any hurry for it to show up. With the manifolds here I'm sure you already know what I want to be doing first. When that's done and I've had some fun with the boat is when I will be ready for a new project.

It's been a busy year so far and it is only half over. Stay tuned and I will let you know how things worked out.

I should be able to find the dock with these.

You would think they would be gold for as much as they cost. I am sure they could have made

them gold for a small, extra fee. Just kidding, they really are nice.

The manifolds were a little tough to install. Like a set of headers on a car but once done I was very happy. They are a lot smaller on the motor then I thought they would be. When you look at pictures of the manifolds they look huge but there not. They only weigh about 12lbs each as opposed to the Osco's that weigh 73lbs each. That is weight saving of over 122lbs. That alone is worth it. I was able to take a short test drive with them but I spent most of my time chasing switched spark plug wires. I did that being in to much of a hurry and when I was out on the water I didn't have my manual with the firing order in it. So, it took a little while to figure it out. After I did it was sweet and I knew it was only going to get better from here on. I am sure the motor could have used a tune up and some tweaking after all the problems I had earlier in the year but it still ran better then ever before. With the old exhaust I was having water reversion happening at low RPM's and that made life tough in the land of 6mph zones. Also starting the motor was much easier. Again with reversion water would end up on the rear spark plugs and make it hard to start. No more. A quarter revolution of the starter and it is ready to go.

This is a whole new world for me, you guys that have performance motors and are still using cast iron manifolds, you don't know what you are missing. I will never build a performance motor for a boat again before having a good exhaust for it. It doesn't matter how much air you can get in the motor unless you can get it out. And for all you guys that run a big cam your not going to have a option of using anything less.

Looking good!

____________________________________________________________________

Winter Is Back

Winter Is Back

2005/2006

And man does it suck. After having a slow start this year with the paint issues and then the exhaust manifolds that I am still paying for the season was way to short. At the end though everything was near perfect and now I cant wait until next spring.

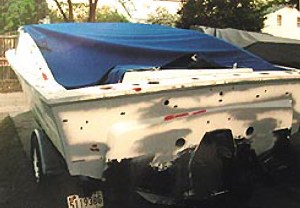

A custom stitched, big blue tarp. It was to big off the shelf so I had to cut it down and run it

through a sewing machine. Yes I can sew. There's nothing wrong with that.

Over the last few months of the season I did make some repairs/replacements but they were elective.

The first and most major was the replacement of the 55 gallon belly gas tank. After more then 30 years I thought it was time. When I first got the boat I couldn't get the gas gage to work even though it was new so I had to replaced the sending unit in the tank. The bad unit I pulled out looked like a giant rust icicle. I would run two in line, fuel filters just to keep crap in the tank from getting to the carburetor. After four years and many gallons of gas I would still see stuff stuck in the second filter. The tank was aluminum and shouldn't have corroded but I know all that stuff didn't come from the bad sending unit alone. Something else was going on and I fixed it with a brand new plastic 30 gallon gas tank.

One of the reasons I went with the smaller 30 gallon tank was that I never filled up the old one. Gas costs to much and why haul around all that extra weight? I figure I wont be doing any off shore races anytime soon. The most I have ever used in a very long day on the water was 20 gallons and around here there is a gas station on every river. Worst case, I have to pull the boat out of the water and trailer it to a gas station. Last, with the big tank I really couldn't tell how much gas I was using. I would drop 30 bucks of gas into it on the way to the boat ramp and it would add up to less then a 1/4 tank. With the smaller tank, as the day goes along and I burn off ten gallons I can see the needle on the gas gage move. The new gas tank is the same length just shorter in height and didn't change the balance of the boat. I also kept the old tank. When I am in need of a project and if the old tank is worth saving I would like to get it shortened in length (make it smaller by 20 gallons). That way I could also move the weight of the gas toward the transom. Moving the weight would help with balancing the boat. Something I will get to later.

The rest of the repairs I made were little things. It is so nice to do little things. The things I always wanted to do but I always had bigger things to do first.

A cold winters night.

Over the winter I still have a list to do to get ready for spring. First, my CD player broke but it was a cheap one off of eBay so it's no big loss. The next thing is a little more complicated. When I installed my new manifolds the weight difference between the cast iron Osco's and the new Stainless Steel manifolds were about a 135lbs and all that weight was right at the transom. Now the bow seems to ride a little low. The Volvo 270 that I have has no trim so there is really no way to raise the bow except for changing the prop some way. I also have a line on a Volvo 290DP with trim but the deal hasn't worked out yet.

Most would be perfectly fine with the way the boat is but I know it can be better so I will have to make it better.

But today there is snow on the ground and the boat has been winterized and put away for the year. I have months to work on deals and plans so there is no big rush. But after this fall I don't care what I get done over the winter. I cant wait until spring!

____________________________________________________________________

Spring 06'

Spring 06'

Winter is over!

When it started I had nothing to do except wait until spring. Now that spring is here I have a lot more then I thought I had to do. I haven't even taken the winter cover off yet but I have boxes of parts. Some I will use and some that will wait until I decide to use them. One of those parts in waiting is a cleat for the transom that matches the bow cleat. Originally it had one where the ski tow is now. I use the ski tow as sort of a transom saver (along with other things) by using a strap between it and the outdrive when towing the boat on a trailer. I haven't had to change a tilt motors since I started using the strap so the ski tow will have to stay for now. The cleat is nice to have just in case I get rid of the ski tow cleat in the future or if I ever get trim for the outdrive.

Now for the parts that I will use. One is a score I made on (where else) ebay. A set of 5 inch pop up cleats for the transom deck. These things are strong, look great and for only 28 bucks shipped to my door. You cant beat that price, trust me I have been trying for a long time. I cant wait to install them and get rid of two more things that are sticking up off the deck now. Then there is the Holman & Moody tag for the outdrive. Have to get that put on so it wont come off again (the rivets are still there from the old tag). Then there is a couple dress up things for the motor.

I still need a new stereo and the bottom has to be painted before it gets to hot this summer along with a list of other things to do.

And again I haven't even taken the winter cover off yet.

I guess you can tell I am sticking with the red theme.

A good weekend came at the end of March and I had to take off the winter cover just to let it air out.

That lasted about 10 seconds before I was on my way to the house for tools and parts. The first thing was one of the hardest. I installed the stern pop up cleats. I didn't realize how hard it would be doing it through a 3" vent hole. The last time I did this was when the boat was apart, now everything was in the way. It only took about 4 hours to pull and reinstall everything but it is done and I love the outcome. One more thing off of my check list.

As simple as 1, 2, 3, 4............ I wish.

As I was installing the cleats I was looking at the rear seats. I was never really happy with the way they looked. They were my first attempt at doing upholstery. After pulling and installing motors and everything else next to them they were looking pretty sad. Also they were sucking up water somehow. I figure I'm using the wrong cushion or something but the stuff I'm using feels a lot better then the "closed cell" foam. I just needed a way to make the new seats "breath" but at the same time water proof.

I had a plan and with most of the vinyl that was left over from the original time I did them (I still could get more if needed). So out came the back and motor cover seats for new vinyl.

I ended up sealing the foam in plastic and in the backside I installed a breather tube that will extend through the seat pan and into the dry part of the boat. If water gets up to the breather tubes I will have more problems then just wet seats. Then I wrapped the whole thing in marine vinyl and added some "piping", something that was missing the last time. They didn't turn out to bad. At least better then they were and if they stay dry I will have won the war.

Another try at doing seat upholstery.

Then there is this. I was talking with Robert Gillingham on Chine Walking.com. He is now in the process of a "top off" restore of his Nova Marine, Nova19. We were talking about inner liners and how they different they were from boat to boat throughout the series and the two builders. Then Barry Munsell came into the forum thread with his info on his boat. You could see the changes but they were still not like mine and then I noticed something in a picture I took to show how mine was in the forum thread. There is a anti slip deck under the foredeck. Why would that be? You cant walk on the deck, there is barley enough room to crawl under there. Then it hit me. The reason my boat's inner liner and decks are totally different is because the hull was laid up as a center console style. Some how it ended up with a top on it. It must have been a "special order". It does also explain a couple things. Next to my hull number that is under the deck there is 7 / 73. My boat is titled a 1972. I believe that was because Allmand stopped making the Super Nova style in 1972 and in 1973 was only making center console Nova's. How this one ended up like it is, is still a mystery. The hull numbers before and after are both center console boats and not finding any with a higher hull number after five years of searching you may be looking at the last Nova19 made.

Why would there be anti slip deck here where no one could ever walk?

You learn something new and a new mystery is born everyday with this boat.

Just a couple updates for the end of spring. I have been out a couple times but gas is so expensive that I elected to take a week off and do a couple more things on my "list of things to do". One I did a couple day ago. It was the Holman / Moody tag that goes on the outdrive. Of course I had to go to H/D for a new set of drill bits because all mine were dead but it was a small price to pay. Especially since I got the tag for free.

Today I had a whole day to do anything I wanted and for as long as I can remember I could do elective things. Being a gear head the first thing I thought of was the motor. Lately it has not been looking as good as it has been running. One part that was really looking bad was the aluminum intake. No matter what I did I could never keep it clean. So today I did something about it. I about striped the motor and painted the whole thing black. I was a little nervous at first about doing it but all and all it turned out nice and a lot better then expected. I also added the red wire looms that have been sitting around forever. It is not a 100% in this picture but it's close. With a little tweaking it's going to be awesome!

Back In Black!

____________________________________________________________________

Volvo 270 With Trim

Volvo 270 With Trim

You would have thought that the above was good enough for a spring project but then something happened that changed everything.

It all started off by wanting to get more bow lift. I always thought there was more speed in the boat if I could get the bow higher on a plain . After a serious look over on what I could do I had noticed that the trim tabs had developed a "hook" in the tab plains That must mean they are active all the time and are always pushing the bow down all the same time. I never used them so this should not be. The first place I go is Bennett Trim Tab company and ask why is this happening? In true Bennett fashion they identify the problem as being the plains I use now were not set up for the speed I run so they sent me all new plains, cylinders and hardware to replace everything. It didn't cost me a penny. That is the way Bennett is the best and if you ever need tabs there is only one place to go! Bennett's service is next to none. To this day they are the best company I ever dealt with in or out of the boating world.

So while I am waiting on the parts to arrive a beautiful weekend comes and I cant resist taking the boat for a ride. I plug up all the holes in the transom and off I go. I didn't notice any difference in the boat with the tabs gone as I put it through its paces but then I went back to the ramp and changed the trim pin on the outdrive to the third hole out. When I first took off I noticed a difference but I thought the prop would break loose at anytime like it always would before when I had the tabs on it. I kept giving it gas until WOT and the prop was still hooked up. I just picked up 7mph with the change of a pin and taking off the trim tabs. I also feel if I had a full trim system I could have got more out of it. Now the hunt begins for trim. I must have it!

I have been looking for the parts to build trim system for a few years now off and on but things would never work out. There was design flaws, other priority's and of course money that would always end the idea for a few months before I would pick it up again. So I didn't have much hope when I started a eBay search. The boat was better with the tabs gone and I could move the pin when stopped but the "building a trim system" idea cam back again. As I am looking through the results of my search I see a headline, "Volvo 280 transom shield." When I clicked on it you could have knocked me over with a feather. What pops up? The Holy Grail.............A Volvo 280 "T" transom shield (the "T" stands for trim). I won the auction 3 days later and it wasn't long before I had it. The sad thing is it had been sitting in dirt for a few years and there was a lot of pieces missing. The good news was all the necessary parts were there. A couple trips to the hydraulic line shop and Home Depot for fittings and a lot of cleaning and I had a working 280T transom shield. I also bought a Mercruiser trim pump and all the connections, lines and electrics to make it work. I figure I have about $650.00 in it total so far but now I have to decide, do I take my boat apart? Now? In the best part of the boating season and what if it doesn't work? But I cant wait. It has to happen now so I can work out all the bugs before August when I want to take it to a Nova reunion. So now the fun begins.

You guessed it, time to pull the motor again. What is this the 12th time?

After turning my bilge into a sea of transmission fluid a few times because of changes I had to make I did get the Mercruiser pump to a bunch of home made stuff to the Volvo trim shield and then to the cylinders to work together.

It actually went together pretty simple. It was me that screwed it up a couple times but once I worked through the screw ups I had trim. Its been working fine for 48 hours now as I cross my fingers but I am sure it is still very early in the story.

All of my Volvo 270 bolted right up to it like it had always been there.

More to come as I figure all this out. I went for the first ride today. Still lots of little things to fix. Also the boat was kind of strange to me. Trim really changes the way it drives and the trim "window" is real small. Just something I will have to get used to. I would love to talk to someone who has done this to a Super Nova but out of the six or so that we know of none have trim.

More to come!

____________________________________________________________________

Here We Go Again

Here We Go Again

Well I got about 4 weeks to play with the trim I installed and was just getting the hang of it . The boat was never meant to have trim. For that matter it was never meant to have a outdrive. All was good and I had it out for a night ride on August 8th 2006 the day after my birthday. Around midnight with a almost full moon I was on my way back to the ramp. With the ramp about a mile away I could not resist hitting WOT for one last blast. About 15 seconds into it I hear a faint squeal. That didn't sound right. So I pull back the throttle and take it slow back to the dock. The motor is looping real hard and when I shut it off and look under the motor cover I find a mess.

What looks like mud was my engine's oil.

Come to find out a bad timing chain cover let water pour into the motor at WOT. When it got to the dock there was so much water in it that the down stroke of the pistons was pushing water and oil out the filler cap, dipstick and up the PCV hose. It was everywhere under the motor cover. I herd that squeal before I got to the dock and feared the worse. I was sure the motor would be nothing more then a anchor from that second on but I was wrong. I took it apart and things did not look that bad. Everything survived as far as I could tell except for the crank which has some slight strands on it but not to bad to fix. The sad thing was that everything that comes in a master engine kit except for the pistons had to be replaced. I sent the block and crank off to the machine shop to be tanked, cam bearings installed and to have the crank gone over. I also had a pilot bearing installed finally after all these years. As these things were being done I was off to the boat junkyard to find another cast iron timing chain cover and prepping all the rest of the parts for the rebuild.

I have done this so many times that the whole process seemed like I could do it in my sleep. The real problem was money. I just finished the trim shield project and now I knew this one would cost me.

Not where this should be but its ready.

Things seemed to take forever but in reality it was not that long at all. They all fell together like clock work (again I have done this so many times). One thing after another. Again I wanted everything perfect this time like it was before and I was on a time limit so I spared no expense as the bills piled up. 33 days later with every awake, non working moment I had I was done and out for a boat ride. I haven't even worked out the bugs yet but at least its not in pieces under the porch. I also have the best season of all to sort things out before winter so there is a lot to do but what else is new.

____________________________________________________________________

The End

The End

It's "The End" in so many ways.

Three days shy of December 2006 the weather has turned and the end of a season has come. The boat is pretty much put away. Just the big blue tarp and it will be done but I need to leave it off for now. More on that later. It was my longest season in so many ways. I always put the boat away way to early and miss out on the last few and sometimes best weeks. This time I ran it to the end and now they are calling for snow flurries next week, I'm done and in some ways it could not come soon enough. Trust me I will need the time off.

This has been a tough season to say the least and it has left me wondering what the hell I was doing. It all started off so good. It was ready to go when it came out of winterization this spring. Everything was fine and then I found the 280T transom shield. I thought that I didn't have any projects planned and there it was on eBay. It was a perfect thing to do. Well it ran into a few bucks more then I thought it would like all projects of this type do but it was the only project in the works. No big deal.

Then came the 33 Days of Hell right after that. Wasn't ready for that but it had to be done or I would have missed the whole fall (my favorite part of the boating season). I stretched, pulled and broke the budget and myself just to get it done and being back in such a short time was a proud moment for me. I would have been done in half the time if I didn't have to wait on the machine shop. I even had the crank drilled for a pilot bearing. Something I wanted to do since the first motor build. I did everything I wanted to or should have in the past. This time I wanted it right! After all that the motor was back better then ever and for a couple months it was a dream.

So I am tweaking and figuring on what I am going to do over the winter to get it hooked up right. For some reason I was in the high teens when it came to prop slip. Not good but I was still out for what could have been lost months so I'm happy.

Then two weekends ago with hardly anyone on the water I took the boat for 27.5 mile straight run each way down to the Bay Bridge and back. Something I've not done in years. What a great ride. The whole reason I own a boat.

____________________________________________________________________

Last Ride

Last Ride

Now last weekend was the "last ride" and I do my normal last ride rituals. It was cold so I may have gone 10 miles overall with 3 or 4 stops. Everything is pretty normal. Starts getting dark and I am on my way home. About two miles from the boat ramp I am running around 3800rpm's. A little hot but nothing insane when WOT is 4700rpm's. The 4's are not even open when I start to hear it . Tap, tap, tap, tap, bang, bang, Bang, BANG, BANG, BANG. I knew in a second what it was. The motor just through a rod or like our English friends say, "I ran a big end and retired with expensive noises".

The sad part was, I was two miles from the ramp and I was alone. No other option but to drive it and I did. I'm sure the bottom end is trashed and this time all I can say is, "I didn't do it". For the first time it wasn't something I did or associated with something I did. It just happened. I will find out later what did happen but I am really in no big hurry. The motor has served me well and even a bullet proof motor only take so much abuse. Now I am weighing my options of what it will cost to fix the 360 in the best case scenario. Like I said I haven't looked at it yet but things don't bang around like that with out doing bad and expensive things and remember with Mopar everything is very expensive.

Then there is what it will cost to do something else entirely. Its feels time for a change in a big way. I just don't have it in me to spend another ton of money just to keep getting back to where I was with the Mopar. I think its time to make the big leap. If this doesn't work out I am thinking outboard.

On a side note I also took the dash panel out to be redone. To many holes of things that were not there anymore. Also things have been spread all over the place. A little layout redesign and a new skin and it will be good as new. It only took about a hour to get out. I figure it will take all day to get back in but if I can find the right material to make it out of it will be worth it.

This will be the third time redoing this panel and what a pain it is to get in and out.

This is just the beginning. There is so much to come in the next couple months I don't even want to think about it. Just need to take it one step at a time. I hope I'll see the water again by mid summer but we will see.

____________________________________________________________________

A New Year

A New Year

A new page must mean some big changes.

I made a decision. Its time for a change and as the New Year approaches the motor work is ahead of schedule. There is still a ton to do and buy but I never thought I would be as far along as I am now. I am sure something will come along and screw that up sooner or later but for now while I am waiting for parts I think I will start / finish another project and get it out of the way. After I took the tilt system out and trim tabs off because I added the 280T transom shield with trim I have had to shift a few things around on the dash to cover the holes left behind and it still had a big hole where the trim tab controller was. With to much going on this summer and fall I never got around to fixing it. So as I put the boat away this fall I spent a hour or two pulling out the dash board for a third time. Today I decided on how I was going to lay it out and then I refaced the board with new laminate. I did it a whole lot easier then I did the first time. I got just the right bit for my Dremmel and from there it was a piece of cake. Its really nice to have the right tool for the job.

This is how it looked the day before I put it away.

There is the little patch and its way to crowded.

The first thing I did was sand the face of the dash with some heavy sand paper to rough it up good. Then brushed Contact on both pieces and let set up. Put the two pieces together and roll the whole thing out. Then I gave it a hour or so while I used Photo Shop to move some things around to see what it would look like. Its pretty cool to see the results before you build something. Looking at it on the floor I would have never came up with the look I wanted and would work but when you can grab switches and move them around or take them out all together with a "click of a mouse" it gets real easy to try everything.

How it looks in my basement tonight.

It still has the protective plastic on it is why it looks a little funky.

This is what I came up with. I really like the way it looks and this set up will leave room if needed for other things later. Like after installing the big block if the boats need the trim tabs back on there will be a space for the controler that will look right . If I find I don't need to add anything I will find something to balance out the depth finder gage in the center. I also should get the name put back on there somehow. I just haven't figured out how I want it yet.

And this what it should look like when it is finally installed in the spring.

Its amazing what you can do with photo shop.

____________________________________________________________________

1/7/2007

I have to say this has been a amazing winter. Yesterday it was 72* out and today it was in the low 50's.

I couldn't pass up a chance like this to get this little project out of the way. When I pulled the dash out I never thought there would be a chance to put it back in until spring but it came and even thought they were calling for rain later, I jumped on it.

Also come spring I want to be able to concentrate on the motor only, not spending a day getting this done. That and I am out of parts for the 454 build anyway. I should get to see the big brown truck a lot next week but right now I am at a stop. Well a "stop" on that project.

Last night I got most of the little stuff that I could done and ready for the install of the dash. I wasn't ready for this at all. I never thought mid January I would be installing it so I still didn't have all the pieces yet. I did what I could and found "stand ins" for the things I wanted to replace.

I start around 12 and just finished up around 5. Took a lot longer getting it in then it did taking it out. Go figure.

I still have to replace the knobs. Being different sizes they look a little crooked but that's a easy fix. I can already see one of the best things is going to be moving the horn button over to where the two little gauges are on the right hand side of the steering wheel. Before it was in the middle of the dash and almost out of reach. Now if I can reach the wheel I can reach it at the same time.

I finished up and was in the house for about a half hour and it started to rain so all and all it was a perfect day.

Some would think I'm nuts saying that. Working all day on a boat in January but no one else is going to do it and I want it as nice as "I" can make it. Its not like I could go out and buy a boat like this and paying someone else to do it is not a option. I can barley afford the parts alone so its just me to do it.

Last, when I "Photo Shopped" the picture I wasn't that far off. Pretty cool seeing it done before I even started. I wish you could build motor that way. In the past I even have fooled around with the boats colors. Yellow, gray and black is a very nice combination. Something to think about. Maybe next spring.

All done but I think I have seen this before.

____________________________________________________________________

Winter Has Now Arrived

Winter Has Now Arrived

Nothing is going on but the cold at the moment. Its time is limited though being its already the middle of February 2007. Spring is coming in just a few weeks.

For the time I have not been building the motor and have been stuck in the house I have been looking for some things that would improve the boat. Being I already did what I originally planed to do this winter (the dash) and I am hip deep into a motor I had no plans of doing a few short months ago so I am trying to keep them small.

One thing that I have wanted to change every time I get gas has been the gas fill. I have one of those flush plastic screw in caps. If it gets to cold or to hot the plastic cap sticks inside the inlet and it takes a screw driver to get it open. It just a pain. So I have been cruising eBay for a while now looking for a flip top gas cap and the other day I find one at a reasonable price ($26.99). So now when the motor comes out (just makes it easier and it has to anyway) this spring a new gas cap will be going in. Being from the time period it should look like it was always there and the next time I fill up at a busy gas station I will think it was a the best 26 bucks I ever spent.

A nice little eBay buy.

____________________________________________________________________

Spring 2007

Spring 2007

Here it is June and there really hasn't been any down time since I put the boat away last fall.

I spent the winter building a Chevy 454ci for the boat. It was a long road and has taken about every last dime I had but it is up and running. You can follow the whole story at MOTOR BUILD II and for now I am just working out bugs with it.

There is still a few other things I need to get to though. The first is paint. Again I have issues with it and it is almost time to do something about it but for now all I want to do is ride.

I never did find out what happened to the 360.

I broke down the motor to just the block and it's internals after I pulled it. Looked all through it and didn't see anything. I even spun it a couple times and nothing. So I brought it back to "Shanty Town" and soaked it in some WD-40 and wrapped it up for long term storage. When this project is over and a few others that have nothing to do with boats but more with Shanty Town I think I'm going to fix it or at least find out what's wrong, just because. I did sell off the manifolds. I needed the money back for paying for shipping them for the repairs that had to be made in Australia. I was never really impressed with them anyway. For the money and if I could weld a little bit I could have made 5 sets or more. As for the rest? It is all sitting and waiting for a cold winter day with nothing better to do. It will happen there is no way I can let the "bullet proof motor" die.

A new start.

____________________________________________________________________

Props

Props

May 2007

Things are plugging right along with the “after motor is installed” projects . I am tweaking out a few things and picking a few RPM’s with each one.

The first thing was the prop. Took it over to Don’s Prop Service. A ledged in these parts for his prop work. Don has retired and it took some hunting to find him but when I did I knew my troubles were over. Its funny when you peak someone’s interest that has been doing something for 50+ years and the results are usually awesome. So far this prop thing has not let me down.

Don was the only dealer in the area for these props for the few years they were for sale. I know I had him when I dropped it on his counter. This guy has done 1000’s of props and I have listened to him in the past with other customers. Not that they didn't get a 100% from Don but most don't get a history lesson along with a couple old stories. So I knew it was in good hands when I left it but was not sure what was going to happen next. I figured Don was not doing it at his house.

From what I understand Don has a silent partner now (a much larger, nationally known prop & racing shop that makes money on the side doing Dons and others work for its racing team). This time Don felt it necessary to take the prop to the owner of the company (another old guy). After the shop owner talked to Don a couple minutes he picked up the prop and said, “lets show these kids a thing or two”, then gathered up his shop and the lesson began. I am not sure what all happened next but from what I understand about everyone in the shop got involved with it at one point or another. Doing things “old school” and then running tests with computers and lasers. Don figures that they worked the prop as good as anything they would run on their race boat. Don then added that it was probably even better being how everyone was trying to out do one another.

I feel very lucky that I ended up over 1000 years of experience fixing my little prop.

Then something came up that’s got me a little rattled. The bet is on that my motor cant push it in my boat. They say this is a Donzi 16 prop. My response? If not then there is heads, exhaust and a supercharger. Don just smiled and then said, “I will be calling after the holiday for the results“. I felt like I should study or something.

Almost a work of art.

The prop is no longer a out of true, flat blade, 22P prop. Now its a 14 X 24 and just a perfect as it can be.

____________________________________________________________________

It Doesn't Stop There

It Doesn't Stop There

The MOTOR BUILD II page may be over because I am not building the motor anymore but upgrades are another story.

Its time to get this thing rollin'.

I picked up this set of S/S roller rockers for my 454. I plan on doing a roller cam and lifters also but after reading how out of true that most "stamped steel" rockers are I thought I better get these first. That way I'm sure that they all are 1.7 and I can get a good read on the cam that’s in there now and know how much more to "go for it" with the new one. Not that flat tappet cams are cheap but rollers are a whole lot more money and I would only like to do it once.

It will probably be this winter before I do the cam. To much work and another reason I am doing the rockers now is I am changing the exhaust manifolds also. Once they are off the valve covers are only 5 little bolts away. To easy and might as well get them out of the way and enjoy the little benefit they will add.

A nice rolling box.

Speaking of exhaust manifolds.

Well I knew when I built the 454 the exhaust was not long for this world. Well the manifolds at least. I really thought I would end up with some insanely expensive exhaust. Not as bad as the Mopar was but still....... So I find a buyer for my left over Mopar exhaust and even though I "took a bath" on how much I got for them I still got enough that I could pick up a couple parts and have enough left over to buy these. They are a set of GLM aluminum manifolds. They look just like the cast iron manifolds but besides them being aluminum they are a tiny bit smaller (I sure could use the room) and on the inside they have separate runners built in to them to a collector at the top. They cost $200 a piece but from the looks of it so far I got a really good deal. According to my bathroom scale the cast iron manifolds weigh 42lbs each and these weigh 17lbs each. The Mopar's exhaust weighed 11 lbs each and that’s for 5 and 1/2 times the money. Already having S/S risers from a must buy for the motor build I'm thinking I may have this set up for a while.

Really, really nice for the money.

____________________________________________________________________

Ouch

Ouch

6/17/2007

We have been having some unusual high tides the last couple days and the water is full of junk. I went out a couple miles and had enough of the slalom course. On my way back I herd a wave slap that didn't sound right. When I got the boat on the trailer I found out what happened when water started leaking out of the bottom of the boat from the inside.

In the picture you can see a crack in the corner where the "vee" meets the flat part of the hull. Now to fix it.

That's a crack.

It doesn't look like much but when it lets water in the boat there is no other priority over fixing it even though it's just a flesh wound.

I had to find out ASAP so I took out the grinder to see what was going on. Apparently the chine is just a hollow box attached to the "bath tub". No structure at all but for it's self. I cant fix it from the top even if I was to take the top deck off the boat so I will just have to do it over a few days "building it up" upside down.

Gravity is not my friend. I have thought about smashing a board with a bunch of glass and mat on top of it and wedging it in place until it dries just to finish off the "filling in" but I am a little afraid of the quality control. So its a couple layers and some grinding, a couple more layers, more grinding then a couple big layers to cover the whole thing.

After a couple days of that I was to this point.

Its back together and solid.

After days of upside down fiberglassing the structure was back and stronger then new. No matter what I did I could never get a smooth layer of glass so it took a little fiberglass Bondo to get it all smoothed out. A couple layers of that and it was good to go.

Good as new but..............

____________________________________________________________________

Bottom Paint

Bottom Paint

Spending all that time under the boat one thing I did notice was it needed some work. All this motor work and I haven't painted the bottom of the boat since 2003.

Spent two hours with a little electric power washer trying to knock off bottom paint. Got about no where with it so I went over to the shop to pick up the gas powered one. Well, 3 hours of power washing with enough PSI that tiny flakes were flying 20 feet away and still not done. The power washer only got about 35% of the paint off. Any where the original blue and black bottom paints was it came right off. But then there was the stuff I got from US Boat on clearance many years ago. Where it got a good bite at its not moving. So when I was done power washing the bottom it looked like the dark side of the moon.